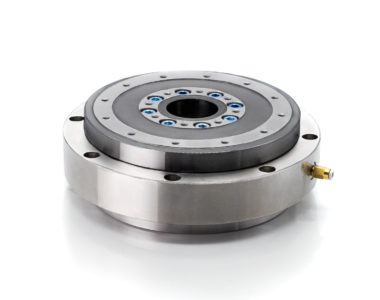

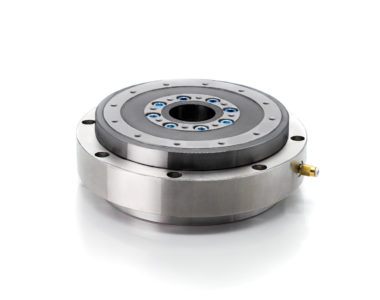

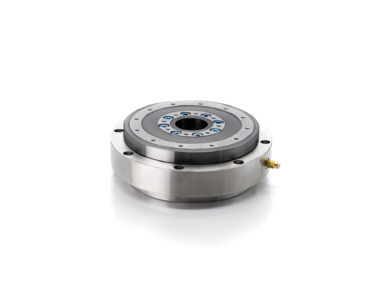

New Way Helps +Vantage Enhance Precision of Inspection Solutions

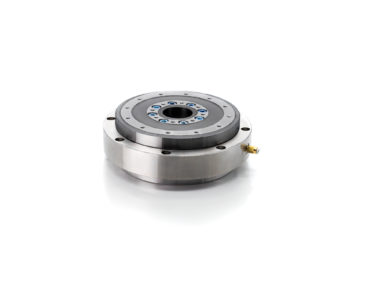

+Vantage Corporation started by providing metrology and assembly solutions to the automation industry, and now provides full integration for robots and sensors. They turned to New Way to help build precision inspection stages, including a piston pin inspection stage built on T-series Air Spindles.