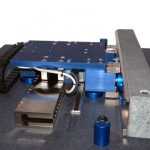

H2W Expands Product Line with New Way’s Products and Services

New Way provided H2W Technologies, a leader in precision motion control solutions, with our Flat Round Air bearings, Air Bushings and Dovetail Linear Slides for integration into large-scale inspection stages requiring exceptional flatness and straightness.