Air Bearing History

Over 200 Years of Innovation

Learn about the history and the advancement of air bearings over the past two centuries. See the growth from early orifice bearings to the Porous Media Technology™ that New Way Air Bearings® manufactures today.

1812

Wills Publishes Earliest Document On Air Bearings

- Robert Wills publishes a book chapter for the Cambridge Philosophical Society titled “On the Pressure Produced on a Flat Surface When Opposed to a Stream of Air Issuing from an Orifice in a Plane Surface.”

- The publication discusses how orifices are used to control air into a gap to carry a particular load. Many air bearing technologies still apply this fundamental principle.

1897

Kingsbury Highlights the Difficulties Faced with Air Bearing Technology

- Albert Kingsbury, attributed with the invention of the tilting-pad thrust bearings that revolutionized thrust bearing designs, experiments with a six-inch diameter journal bearing supported by externally pressurized air.

- This addresses the manufacturing challenge of matching the geometry and size of the bore and shaft to achieve a consistent 0.0005” gap. Small gaps are required when using air because the viscosity is so low.

- New Way founder and chairman Drew Devitt explains the function of air thrust bearings in this video:

1904

George Westinghouse Files for Air Thrust Bearing Patent

- George Westinghouse files a patent to employ air thrust bearings in a vertical steam turbine.

- In addition to offering higher performance than roller bearings, the low-air viscosity and nearly zero-friction operation of thrust bearings prove essential in improving the efficiency of Westinghouse steam turbines.

1960s

DOE National Labs Applies Air Bearings in Ultra-Precise Tools

- Research at the Y-12 National Security Complex develops a new air bearing spindle for machining laser fusion mirrors, nuclear warheads, and spacecraft with larger spherical aspheric parts. The porous graphite spindle developed as a result, is a progenitor of today’s Porous Media Technology.

1961

IBM Commercializes Use of Air Bearings in Hard Discs

- The granddaddy of hard drives uses air bearing spindles to produce large hard discs.

- With motion error around two-millionths of an inch—100 times more accurate than traditional spindles—air bearing spindles allow for higher-data concentrations.

- Today the hard disc drive industry still relies almost exclusively on air bearing spindles for its spin stands.

1965

The Coordinate Measuring Machine is Revolutionized with Air Bearings

- The CheckMate Coordinate Measuring Machine (CMM) first utilizes air bearing technology with a finely-polished granite guide surface.

- Russ Shelton, the originator of CMM, discovers the advantages of building coordinate measuring machines with porous carbon air bearings that offer straighter, Frictionless Motion®️. The silent and smooth operation is very apparent in the measurement and scanning resolution on fly-type machines.

- Most modern CMMs continue to employ air bearings for their exceptional accuracy and resolution.

1982

Sheffield Develops Its Own Air Bearings for Its CMMs

- Sheffield Corporation is one of the few companies to develop its own porous media air bearings.

- Originally employed on the Apollo Machine in 1982, Giddings & Lewis Metrology (of which until 2004, Sheffield was a subsidiary) still continues to use these porous media air bearings.

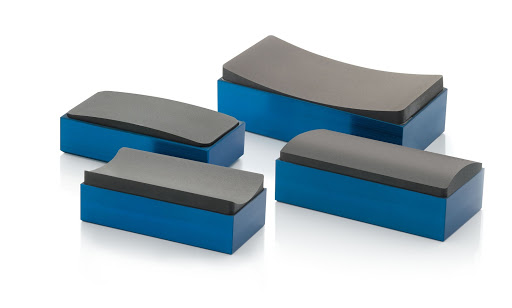

1982-1984

Introduction of Standardized Air Bearings

- The predecessor to New Way Air Bearings, Aeolus Air Bearings introduces the first standardized air bearing products. CMMs mostly utilize these commercially-available air bearings because of their stiffness and stability.

- In 1984, Aeolus offers a standard product line consisting of several sizes of affordable, simple-to-install air bearings.

1987

Starrett Begins Using Aeolus Air Bearings on its Coordinate Measuring Machines

- The L.S. Starrett Company redesigns its coordinate measuring machines with Aeolus Air Bearings, incorporating Porous Media Technology instead of developing an in-house line.

1993

Aeolus Becomes New Way

- The name Aeolus Air Bearings changes to New Way to better describe the company’s unique air bearing products and advanced technologies.

1994

TA Instruments Selects New Way Air Bearings

- TA Instruments selects New Way air for their next-generation, dynamic material analyzer.

- Porous Media™ air bearings allow TA Instruments to dominate the DMA market—a position the company still holds today.

1996

New Way Awarded a Patent for Vacuum Replication Process

- New Way receives approval for a patent on its Vacuum Replication Process. This creates a technically and economically effective method of fitting air bearings into precision assemblies in its slide manufacturing operations.

- The company continues to apply this same technology today.

2003

Air Conveying Technology

- New Way begins developing air conveying technology for noncontact handling, processing, inspection, and transport of Flat Panel Display and Photovoltaic glass.

2004

New Way Acquires American Sun

- New Way Air Bearings moves operations into the 35,000 square-foot American Sun facility, creating a new, precision-friendly, environmentally-controlled manufacturing environment.

2005

Flat Panel Display Market

- New Way launches conveyor air bearings and precision chucks for the flat panel display OEM market.

2007-2009

New Way Earns Position on the Inc. 5000

- New Way makes the Inc. 5000 list of America’s fastest-growing private companies for three consecutive years.

- In 2008, New Way achieves ISO 9001:2000 certification.

2009

New Way Introduces Radial Air Bearing Line and Academic Program

- New Way introduces a line of Porous Media Radial Air Bearings engineered to deliver frictionless rotary motion for precision applications.

- The same year, the company launches an academic program that provides university engineering and science educators with the tools and training to learn about Frictionless Motion®️.

2010

FlexTech Alliance Contract

- FlexTech Alliance awards New Way a contract to develop a noncontact vacuum seal.

- This allows for small, and potentially wide vacuum chambers appropriate for chemical vapor deposition, physical vapor deposition, or other processes requiring deep vacuum.

2011

Patent for Air Bar Concept

- New Way issues a patent for a non-contacting Porous Media Air Bearing and glass flattening device.

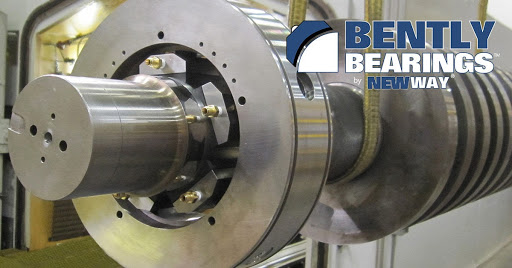

2017

New Way Acquires Bently Bearings™

- New Way expands its product line with pressurized gas bearings offered under the name of Bently Bearings.

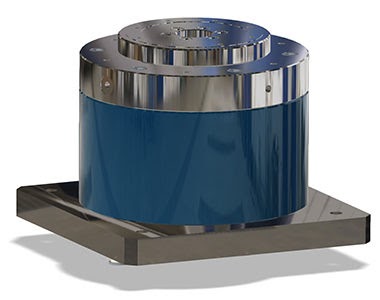

2019

New Way Introduces Servo-Driven Rotary Stages

- New Way announces the addition of Servo-Driven Rotary Stages to its standard air bearing product line.

- The product combines New Way Air Spindles with high performing motors/encoders, creating a fully integrated solution for precision rotary stages.

Bring Your Process into the Future

Let your process be the next step in the history of air bearings. Download our eBook to learn why so many industries have made the jump to Porous Media Air Bearings, and how your application can benefit. Have a more specific question? Contact us 24/7 to discuss your custom application, and how New Way Air Bearings can impact your process.

Discover How Air Bearings

Deliver Disruptive Innovation

In 5 Industries

Get the eBook

Find Out What

Porous Media Air Bearings

Can Do For You

Download the Infographic

Contact us today for a complimentary consultation