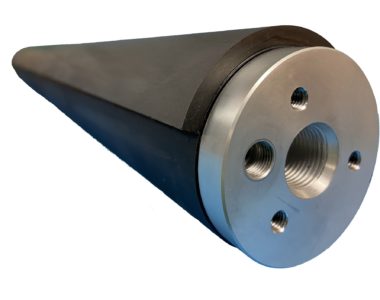

ISARA400: World's Most Accurate 3D CMM Featuring New Way Air Bearings

New Way Air Bearings has a long and fruitful relationship with IBS Precision Engineering, a pioneer in coordinate measuring machines. Their latest innovation, the ISARA400, uses flat round air bearings to 50nm level precision across a three-dimensional measurement space.