The Air Bearing Application and Design Guide

New Way Air Bearings® has taken great care to compile all the technical know-how our customers are looking for in one convenient place: The Air Bearing Application and Design Guide. This 70 page PDF forms a comprehensive, start-to-finish document so you can evaluate all aspects of air bearings, and make your decision on our products having the utmost confidence.

- Part One: Understanding Air Bearings

- Part Two: Choosing Air Bearings

- Part Three: Designing with Air Bearings

- Part Four: Setting up and Using Air Bearings

- Part Five: Additional Information

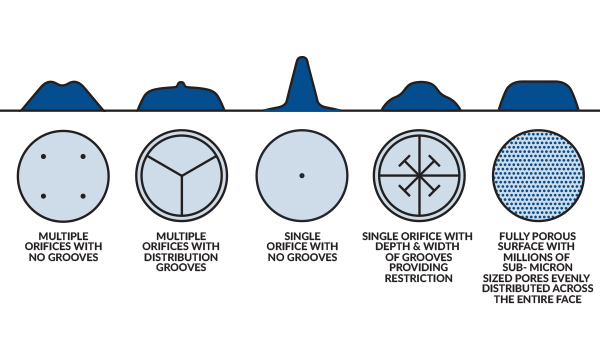

Part One is your introduction to the air bearing and why we’ve devoted our company to the pursuit of Frictionless Motion®️. This section covers the benefits derived from air bearing operation, and their advantages compared with contact bearings and orifice bearings. It also covers technical data on stiffness, compliance, lift/load curves, and stability. Part one concludes with a brief overview of relevant industries for air bearings, as well as our current product line.

Part Two provides you with a convenient table for comparing our selection of Flat Pads, Bushings, Vacuum Preloaded bearings, and stages against their respective characteristics. This includes cross-referencing cost, assembly, precision, load capacity, and other relevant factors. This section also covers environmental effects on bearing operation, such as the results of dust, oil, water, and temperature, allowing you to choose the right bearing for your operating environment.

For the customers keen on understanding how air bearings will fit into their process, Part Three is your bread and butter. In this section, we cover requirements for using air bearings—like surface finishing and local flatness—as well as a comprehensive overview of how and when to preload your bearings.

This section discusses how air bearings handle holes and imperfections in a guideway, as well as the distinction between pre-loading for static and dynamic systems. This section is ideal for engineers planning to retrofit porous media bearings into an existing system, and will allow you to readily determine compatibility with your existing guide surface.

For further technical information on air bearing performance, durability, vibratory behavior, and analytical modeling, please see our technical reports.

This section focuses on how to set up and integrate air bearings. We provide an in-depth look at all our available mounting hardware, to make installation and retrofitting a breeze. This includes achieving optimal operation with our self-leveling, adjustable ball mounts. Part four also covers how to adjust preloaded bearings, and numerous configurations for flat air bearings in linear and rotary applications, allowing you to identify the configuration that best fits your needs.

Part Five covers the aspects of air bearing operation that concern air supply, filtering, and the necessary equipment to ensure your air bearings are operating in an ideal capacity. Here, we discuss ISO classifications for air cleanliness based upon dirt, water, and oil content, as well as providing the necessary equations and charts so you can calculate and provide the correct volumetric flow to your bearings.

Contact Us

If you’ve read through the guide and want to discuss your application with us, or simply have a question to ask, don’t hesitate to reach out to us!

Discover the Porous Media Difference Today