The variety of markets taking advantage of the benefits provided by Porous Media™ is expansive and ever growing. Where once our non-contact products were limited to semiconductor manufacture and flat panel transportation, our customers have used their ingenuity, combined with New Way’s in house design team, to expand our products into fields like automotive testing, for true force dynamometry and computed tomography, for faster, quieter CT scans. Air Bearings are building the future with additive manufacturing, ensuring precision through nanometer accurate metrological sensors and providing the foundation for a new generation of medical implants. See what New Way has done for your industry, and if your business is new to Air Bearings, New Way is here to help!

Aerospace Manufacturing

Whether it be civil or defense, in the atmosphere or hard vacuum, precision motion is crucial to developing these technologies.

Agriculture

New Way Air Bearings provide an ideal platform for agriculture, an industry which requires absolute resiliency and reliability in their dynamic components.

Automation Testing

New Way Air Bearings provide an ideal platform for automated testing, coordinate verification and other inline quality control processes.

Energy Markets

Three Applications for New Way Air Bearings in the Energy Industry

Federal and Defense

New Way Air Bearings provide an ideal platform for defense applications that require precision tracking and degraded environment operation.

Food and Beverage

Whether your process requires heat, cold, grinding, milling, or simply around-the-clock reliability for product conveyance, Porous Media Technology™ delivers the solution you’re looking for.

Industrial Construction

New Way brings robust bearing solutions to manufacturing and industrial construction in an industry that turns labor and material efficiencies into a competitive advantage.

Laboratory Instrumentation

Whether governmental, academic or privately owned, precision and repeatability in scientific laboratories is of the utmost importance. At New Way we understand this need for uncompromising performance.

Marine Markets

Air Bearing technology offers immense value in the marine industry, both within shipyards and the larger shipping industry as a whole.

Materials Handling Markets

New Way Air Bearings® are ideal for materials processing stages across numerous industries.

Textiles and Composites Markets

Noncontact air bearings in the textiles and composites manufacturing sector

Automobile Testing

Frictionless motion enables rolling wind tunnels and true force dynamometry.

Bulk Powder Handling

Learn how Porous Media™ air bearings will revolutionize every corner of the bulk powder handling industry.

Computed Tomography

Radial Air Bearings allow for quieter, faster scans and greater patient comfort.

Flat Panel Display

With a combination of positive pressure and applied vacuum, air bearings allow for rapid, precise handling of FPD’s.

Flexible Web

Air Bearings allow for flexible web transportation with up to 180 degree bend angle and adjustable fly height.

Medical Markets

Zero friction means no overshoot, and the capability to produce implants perfectly fitted to each patient.

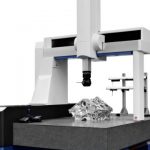

Metrology

Truly repeatable motion offers meteorological instruments motion with virtually no hysteresis error.

Other Markets

The benefits of air bearings make them ideal for applications in a broad range of markets, from food processing to solar cell manufacturing

Precision Machine Tool

High stiffness and damping make air bearings an ideal choice for tooling assemblies.

Semiconductor Precision Air Bearings

Cleanroom compatibility and no lubrication make air bearings the perfect fit for semiconductor manufacture and wafer inspection.

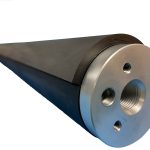

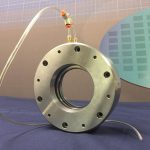

Shaft Seals

The New-Seal™ combines a bearing and a seal into one unit, perfect for rotating applications working off process gases.

Vehicle Testing

New Way® Air Bearings provides an array of Frictionless Motion®️TM solutions to overcome common challenges in vehicle testing.Contact us today for a complimentary consultation