Need a frictionless spherical bearing for flexible film? Let us help!

Flexible films are THE market everyone wants in on.

With projected growth from $29 billion in 2017 to $73 billion in 2027, roll-to-roll manufacturers are scrambling to determine the right components for their flexible film production.

There are numerous components to consider within roll-to-roll (R2R) production, each designed to solve a different problem.

With this in mind, we’ll continue the series examining various web handling products offered by New Way®.

In this edition, we’ll take a closer look at a component offering Frictionless Motion®️TM for heavy vertical loads, high precision, and production increase for flexible film.

Meet spherical air bearings.

Evolution of Spherical Bearing Design

Spherical bearings are a popular choice in roll-to-roll systems as they are ideal for downward loads with the ability to operate with a level of misalignment. Additionally, their design allows for easy removal of rollers requiring no disassembly of the bearing housings that support the roller.

Recognizing the impacts of maintenance on production numbers and profits, ‘maintenance-free’ spherical bearings were created. In this design, contact is made against a non-stick surface such as PTFE (TeflonTM is a common brand name) known to have the lowest coefficient of friction among existing solids, eliminating the need for relubrication.

Spherical air bearings take the concept of ‘maintenance-free’ to a new level. Using a thin layer of pressurized air, the sphere is supported with no contact, providing Frictionless Motion®️.

Choosing the Right Spherical Air Bearing

Air bearings and the technology behind them is not new, but there are options when it comes to the design. The differentiating feature is how the air is distributed:

- Orifice or grooved—air provided through one (or more) holes

- Porous media—air distributed through millions of sub-micron holes

New Way provides air bearings using its Porous Media TechnologyTM. The use of porous media is superior in its ability to uniformly distribute air pressure across the face of bearing, whereas orifice design can exhibit pressure gradients. The even pressure with porous media simultaneously restricts and dampens the air flow offering greater precision.

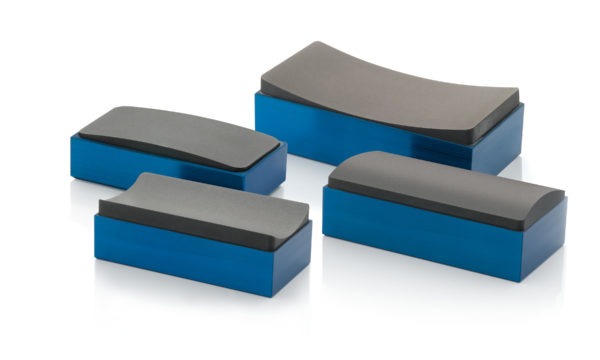

New Way’s spherical air bearings are a natural extension of the flat round air bearings, New Way’s successful first standard air bearing product line. Options for the spherical air bearings include:

- Standard product line with housings available

- Custom spherical bearings with the option to add a vacuum preload

Now, let’s see how this transformative design in spherical air bearings is advancing flexible film production.

3 Ways Spherical Air Bearings are Advancing Manufacturing of Flexible Films

1. Improved Precision

Flexible hybrid electronics demand high precision to ensure printed circuits, sensors, processors, antennas, etc are accurately ‘printed’ on a flexible substrate. The precision of just one substrate can be challenging enough but expand that to a large web for mass production, and precision will make or break your production dreams.

Air bearings utilizing orifice compensation can present pressure gradients impacting the precision of the printed components on the substrate. These pressure gradients can cause damage to the substrate or waste of the product as well as reliability issues in overall production.

The foundation of all New Way products, including spherical air bearings, is the use of its Porous Media Technology. This differentiating design is inherent with zero friction and surface averaging, offering nano-level precision not offered by journal bearings or orifice-based air bearings. This level of precision offers superior reliability within the production line as well as for the operation of the product.

2. Less Maintenance

New Way Porous Media provides Frictionless Motion®️, therefore there are no burdensome lubrication requirements driving downtime, impacting production quantities.

While there are ‘maintenance-free’ spherical bearings, these PTFE-lined bearings do make contact but don’t stick. However, over time, this continued contact causes wear on the coating, eventually creating a metal on metal effect as the coating deteriorates.

New Way Spherical Air Bearings make no contact, even at startup, translating to less wear and longer component life. The result is cost savings of new components as well as the impact of maintenance downtime for installation. The net impact is an increase in end production quantities and profits.

3. Simplified Assembly

New Way spherical air bearings provide a streamlined interface to shafts or rollers. The spherical air bearings are fixed to a shaft or roller at either end, allowing for easy service to the shaft/roller if necessary.

Disassembly is accomplished by simply lifting the entire roller with the spheres on either end up and out of the cups that the spheres sit into. No fear of oil/lubrication dripping on your flexible substrate either! This simplistic approach to assembly will save downtime during maintenance and assembly, improving production yield.

Advance your Flexible Film Manufacturing!

The flexible film market has an abundance of innovative ideas, but the obstacle often is overcoming production challenges. Even after a successful prototype production, companies need to be able to have the right equipment to mass produce the film at a reasonable cost.

Here at New Way, we are confident our spherical air bearings can be a part of the solution to turn an innovative, life-changing idea into a production reality. Our spherical air bearings are just one of our web handling solutions able to do just that.

If you are ready to use spherical air bearings to advance your flexible film manufacturing, tell us more about your application so we can help you get started! Or contact us today for a complimentary consultation to learn more about how our Frictionless Motion®️ products can improve your production.

If you missed our first post in the series of our series web handling solutions, you can learn more about air turns here. Stay tuned for our next post in the series highlighting Thrust Bushings.