Air Spindles Provide Fast, Effective, Precise Motion

By and large, most forms of rotary and axial motion rely on spindles for motion and control thereof. Machine Design offers a high level view of spindle configurations, showing how they advanced from being built on a belt and pulley system to designs integrating brushless motors for precise angular control.

As advanced as spindles have become, they’re still prone to common causes of contact machinery failure. At New Way®, we have innovated our air spindles and servo-driven rotary stages, powering the next generation of rotary applications.

The Drawbacks of Traditional Spindles

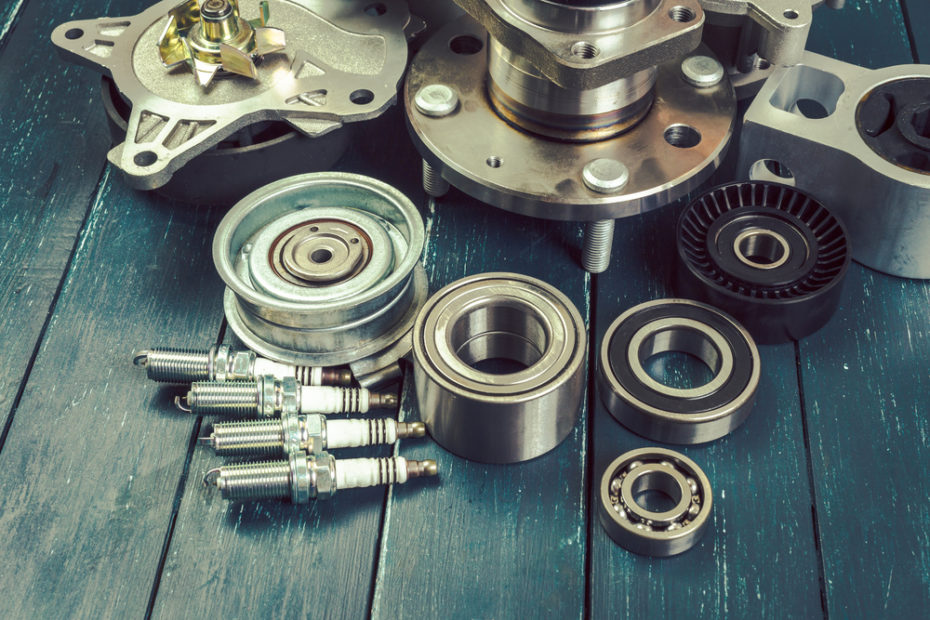

Traditional spindle designs utilize a rotating shaft for axial motion, supported by either angular contact bearings, tapered roller bearings or potentially even double tapered bearings. These systems offer high load capabilities and stiffness, but fall victim to the numerous effects of contact motion, such as:

- Rust induced by water based lubricants

- Humidity induced by thermal cycling, which in turn creates a vacuum, drawing warm air into the spindle

- Thermal instability when preloaded

- Limited lifespans due to spalling and flaking of bearing surfaces

Advancing Spindles with Porous Media™

New Way has already demonstrated the wide applicability of porous media based solutions for rotary motion across such fields as automobile testing and metrology. Now, we have a dedicated lineup of products to support spindle application, separate from our lineup of radial air bearings

Air Spindles

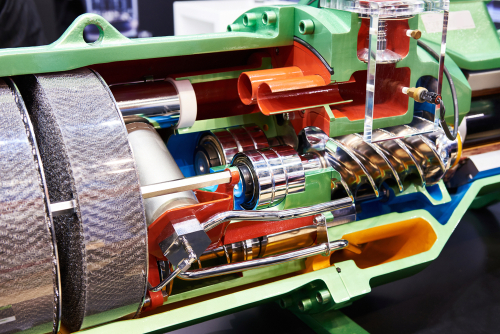

New Way air spindles are a revolutionary step for rotary motion. Eliminating contact bearings and sidestepping complicated technology, like magnetic suspension or high pressure oil systems, we use our Externally Pressurized Porous Media to suspend the rotor above the stator on a five micrometer-thin cushion of air. This averages out any surface imperfection and removes all friction, resulting in sub micron synchronous error and all but eliminating asynchronous error.

New Way air spindles are a revolutionary step for rotary motion. Eliminating contact bearings and sidestepping complicated technology, like magnetic suspension or high pressure oil systems, we use our Externally Pressurized Porous Media to suspend the rotor above the stator on a five micrometer-thin cushion of air. This averages out any surface imperfection and removes all friction, resulting in sub micron synchronous error and all but eliminating asynchronous error.

Without friction to contend with, air spindles offer an order of magnitude increase in speed over their bearing-based predecessors, while eliminating the wear and tear, and eventual repair which would come with a contact system.

Click here to read the full brochure on our T-Series line of air spindles and see the full list of specifications, including:

- Dimensions

- Input pressure

- Axial load

- Radial load

- Error motion

- Maximum speed

- Load flow

- Moment of inertia

The full air spindle product line ranges from the 55mm SS-55 up to the 375mm SS-375, and all of our air spindle products are ISO Class 3 cleanroom compatible.

Servo-Driven Rotary Stages

In addition to developing a non-contact spindle solution, New Way has gone one step further with our Servo-Driven Rotary Stage. The Servo-Driven Rotary Stage is our all-in-one solution for precision rotary motion, and houses one of our air spindles, coupled with a slot, brushless motor and a 1.1 arcsecond precision rotary encoder.

The air spindle allows for smooth, precise motion and the spotless motor removes the cogging-torque effect, allowing for a direct relation between current supplied and torque produced. Coupled with a 1.1 arcsecond (or 1/36,00th of a degree) rotary encoder, we have a system capable of 1,184,000 counts/rev, for unmatched precision.

The Servo Driven Rotary Stage offers immense potential for rotary inspection stages, but it’s already produced stellar results, acting as the foundation for the Keck Observatory’s azimuth encoder. Before New Way got involved, their mechanical roller track required frequent maintenance for oiling and the system eventually lost accuracy, as friction caused the encoder to slip. Now, the telescope’s nanoscale accuracy is unencumbered by friction and enhanced by the addition of a porous media based solution.

The Servo Driven Rotary Stage is offered in the RT-100 and RT-150 configurations, both of which are available in standard or high precision rotary encoder

Contact Us

If you’d like to discuss your ideas or applications for air spindles or a servo driven rotary stage, please contact us so we can discuss how New Way Air Bearings can meet your needs!