Orifice vs. Porous Media Air Bearings

For as long as they have existed, air bearings have primarily occupied a peculiar design space—part curiosity, part revolutionary, and often difficult to manufacture, the air bearing’s incredible potential has been recognized for centuries.

Now, New Way Air Bearings® would like to take this opportunity to provide you with a history of the air bearing and a technical comparison between the long standing orifice bearing and New Way’s own air bearings built on Porous Media Technology™.

A Brief History of Air Bearings

The air bearing’s long and distinguished history traces its roots from Victorian England through the hands of American luminaries, helping to achieve man’s first steps on the moon and enable the precision manufacturing capabilities we all know and love today.

- 1828 – Robert Wills publishes “On the Pressure Produced on a Flat Surface When Opposed to a Stream of Air Issuing from an Orifice in a Plane Surface” in the Cambridge Philosophical Society. Wills publication outlines the most basic principle by which orifice or porous media air bearings operate, that of pressurized air exiting an orifice and producing a pressure gradient against an opposing surface.

- 1897 – Albert Kingsbury invents the tilting-pad thrust bearing. His experimentation with a six-inch diameter journal bearing supported on an external air supply, revolutionizes the design of thrust bushing and bearings. Kingsbury’s innovations would ultimately be constrained by the manufacturing techniques available at the time, as the bore and shaft required a consistent 0.0005” gap to properly function.

- 1904 – The tycoon George Westinghouse (most well known for being Nikola Tesla’s financier during the infamous War of the Currents) receives a patent for a thrust bearing integrated into a vertical steam turbine. A prolific engineer and inventor in his own right, he leveraged the knowledge gained from his invention of the locomotive air brake into pneumatic power generation for maritime use, wherein he saw an early iteration of the air bearing as a vital component for success. Air’s naturally low viscosity combined with nearly Frictionless Motion®️ was an important factor in the high efficiency of Westinghouse’s steam turbine.

- 1950’s/1960’s – US National Laboratories utilizes air bearings as part of its first diamond-cutting technology to machine laser fusion mirrors, missiles, and spacecraft with aspheric parts. The diamond cutter would be used to machine mirror surface finished three-meter wide optical components, with accuracy measured in fractions of light’s wavelength. The air bearing formed the machine spindle, and National Labs would later lead the development of Porous Media Technology, the foundation for New Way’s air bearings.

- 1961 – IBM commercializes the usage of air bearings in their first generation of hard drives. Boasting error motion on the order of two millionth of an inch and 100 times more accurate than contact bearing spindles, air spindles allowed for higher data concentration, and even today, air bearing spindles are still a necessity for the hard drive disk industry.

- 1965 – Russ Shelton, the father of the Checkmate Coordinate Measuring Machine (CMM) discovers the benefits of developing a CMM machine with an air bearing and a polished-granite guide surface. Air bearings are now the gold standard for CMM machines, owing to their silent operation and smooth, repeatable motion.

To learn more about the recent history of both air bearings and New Way Air Bearings, our Air Bearing History page covers the foundation of New Way and the expansion of our product line.

Air Bearing Technology: Orifice vs. Porous

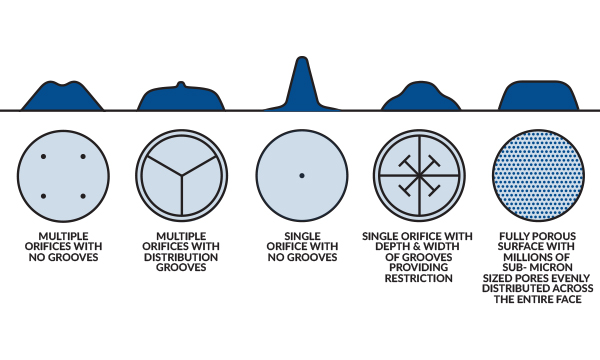

For the vast majority of the air bearing’s nearly 200 year-long history, they have largely existed in one form: the orifice bearing. Orifice bearings function by forcing air through orifices or grooves in the plate to generate their air cushion.

Both the number or orifices, groove patterns, and depth must all be evaluated and redesigned for every individual application of the orifice bearing, making them extremely difficult to manufacture. And, requiring a build-it-yourself approach that most companies simply don’t see as falling on the correct side of the cost-benefit chart.

The orifice bearing was broadly considered the only design by which an air bearing could function until Aeolus Air Bearings, better known today as New Way Air Bearings, charted a new course with our Porous Media Technology.

Externally pressurized Porous Media changed the definition for air bearings, what they could do, and how they could function. By forcing air through millions of sub-micron pores evenly distributed across the porous carbon face, we’ve solved virtually every problem plaguing orifice bearings, and opened the technology to new applications and industries.

Stability and Porous Compensation

When selecting a bearing for usage, stability often comes out on top as your primary concern. Unfortunately, traditional orifice bearings can not always be trusted to provide stability during operation. Due to the inherently unequal distribution of air across an orifice bearing’s face, they’re potentially subject to an instability known as the “pneumatic hammer effect,” which occurs when the air is restricted by a gap slightly smaller than one which allows equilibrium.

If this occurs, air pressure will increase and displace the bearing upwards, causing both pressure and the bearing itself to drop and repeat the cycle. This continues until the entire assembly oscillates at its resonant frequency; the exact same effect which destroyed the Tacoma Narrows Bridge in 1940.

As we can see in the graph above , even when orifice bearings utilize multiple patterns of holes and grooves, no matter the configuration of the holes or the depth of the grooves, it’s virtually impossible for them to produce an even pressure gradient across the bearing surface.

In theory, the perfect air bearing would supply air pressure equally across the whole face of the bearing, while automatically restricting and damping airflow at the same time. The porous media air bearing checks all of these boxes by forcing air through the torturous passageways of the porous carbon. By diffusing air through millions of sub-micron holes, a perfectly even pressure gradient is created, which simultaneously resists changes to the volumetric flow of air, resulting in a damping effect that creates a naturally stable air bearing.

Stiffness

Once stability has been ensured, stiffness often rises to become the most important performance characteristic one considers when evaluating air bearings.

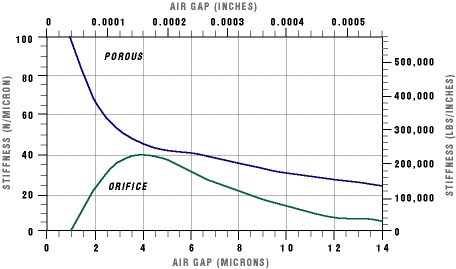

We define stiffness as the ratio of the change in air-film thickness in response to a change in load. Therefore, the stiffness of an air bearing is highly dependent and correlated with the thickness of the air film. This relationship leads to a corollary: A thicker air gap is more compressible, so in order to optimize for stiffness, we must minimize the air gap.

Collapse occurs when an air bearing’s fly height is reduced to such a small gap that the region is starved for flow and pressure. Observing the above graph, we see that porous bearings and orifice bearings exhibit opposing relations in response to a decreasing air gap: Porous bearings become stiffer while orifice bearings lose all stiffness, or in other words, they collapse.

The effects of traditional air-bearing collapse also extends to the physics and operation of an air bearing’s initial lift off as it’s being pressurized. For an orifice bearing which is grounded by a force or loading, it will require a high percentage of operating pressure before the bearing “pops off” the guide surface due to flow across the orifice face. This is caused by the comparatively small lifting surface available to the orifice bearing, which pushes air only through the area of its orifices. Comparatively, a porous bearing has its entire surface area to act as a lifting surface.

Consulting the graph above once more, a porous media air bearing requires a low percentage of the operating pressure, and additionally, the film thickness increases as pressure increases. This is a result of pressure bleeding across the entire face of the bearing, meaning a lesser dependency on airflow across the bearing face. This unique phenomenon results in far higher stiffness for porous bearings, even at lower film thicknesses.

Indeed, as we observe the left-hand side of the graph, the porous media curve shoots up below four microns—the result of a squeeze-film damping effect. Curiously and advantageously, this results in increased damping being positively correlated with increased stiffness, a relationship almost unheard of in machine design and system analysis.

Crash Resistance

Increasing stiffness creates a bearing that’s more difficult to crash, an important safety feature for any precision-minded industry.

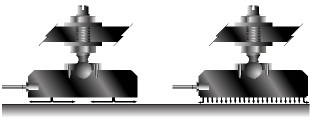

In the event of an unexpected touchdown, the aftermath is markedly different when comparing orifice versus porous media bearings. The hard surface of an orifice bearing—often coated aluminum, stainless steel, and nickel—are capable of scratching or gauging a granite or even steel-guide surface beyond usability.

Meanwhile, the softer surface of a porous carbon bearing will not mar its guide surface. Should a touchdown occur, the bearing’s soft graphite surface (with a compression strength of 91 MPa) will sustain the blow. And, even if it becomes scratched or marred, the uniform pressure distribution means it can operate largely unimpeded, even with sizable damage to the bearing face.

At worst, a scratched porous bearing will fly somewhat lower while a scratched orifice bearing will collapse entirely as air will follow the path of least resistance (i.e. the scratch instead of the intended groove pathways). Contend this with the fact that guideways can only sustain scratches or blemishes up to 0.002” deep, and the porous advantage is obvious.

Air Consumption

While porous air bearings and orifice bearings differ along their performance specifications, porous bearings also offer a greater value when it comes to air consumption. The natural permeability of our porous carbon acts as an airflow restrictor and naturally reduces the flow of air through the bearing. This results in a volumetric airflow measured on the order of standard cubic feet per hour, opposed to an orifice bearing with a flow typically measured by standard cubic feet per minute.

Once again the porous bearing demonstrates an order of magnitude improvement over its orifice-based counterpart. The drastically reduced airflow results in lower upkeep cost, reducing compressor usage, and saving electricity.

Cleanroom Compatibility

With more high-tech manufacturing moving towards increasingly tight tolerances and miniaturized architecture, cleanroom standards are rapidly becoming a necessity for many businesses. Semiconductors, optical equipment, satellites, and biomedical equipment all require cleanroom compliant facilities in order to be manufactured to spec, and require bearing technology capable of meeting that standard.

Traditional contact bearings often create a bottleneck in the transformation of a manufacturing process into a cleanroom compliant one. Contact bearings need lubrication, which can aerosolize, and as their dynamic components wear down and spall, can also become airborne particulates and contaminate your environment.

Since air bearings are an entirely noncontact technology, they don’t face the issue of generating their only particulates or injecting outside contaminants into a cleanroom.

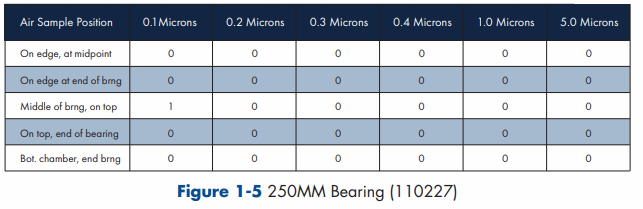

A test undertaken by New Way Air Bearings demonstrated the inherent compatibility of air bearing products to an ISO 16444-1 Class 3 cleanroom environment. Per the parameters of this test, a 250mm Air Bar was mounted inside of a 12’ x 6’ x 8’ air tight chamber, with a sampling system powered by a Lasair II 110 system, capable of extrapolating readings and normalizing them to create measurements per cubic meter. An ION gun was used to purge the chamber to Class 1 cleanliness in preparation of the tank and the air supply was filtered down to 0.1 microns before it was fed into the air bar.

The test results shown above, demonstrate that only a single 0.1 micron-sized particle was produced by the air bearing. When we consider that an air bearing may take as long as one hour to supply one cubic meter of air, and that a cleanroom may exchange its air supply up to 10 times per minute, we see clear compatibility with ISO class 3, and even a strong argument for ISO Class 1 cleanroom compliance.

This remarkable property of the air bearing is owed to its porous media structure, which functions as a submicron filter, removing particulates before they can pass through the bearing’s porous structure.

To learn more about the myriad benefits air bearings provide, visit our technology comparison page to learn more.

Contact Us

If the remarkable abilities of New Way’s porous media air bearings sound like an ideal fit for your business or manufacturing process, please reach out to us so we can discuss what New Way Air Bearings can do for you!

Contact us today for a complimentary consultation