General Air Bearing Care

- Keep the guideway and bearing surfaces clean of debris and excessive dust.

- Avoid contaminants with oil, coolant, or other fluids.

- Clean porous media and guide surfaces with 60 psi (0.41 MPa) air pressure applied.

- Clean using Isopropyl Alcohol 70% ONLY.

- Do not clean bearings or guide surfaces with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping guide surfaces thoroughly.

- After cleaning allow the alcohol to evaporate completely.

- Also, allow guide surfaces to dry completely before passing bearings over the newly cleaned areas.

Product Specific Care

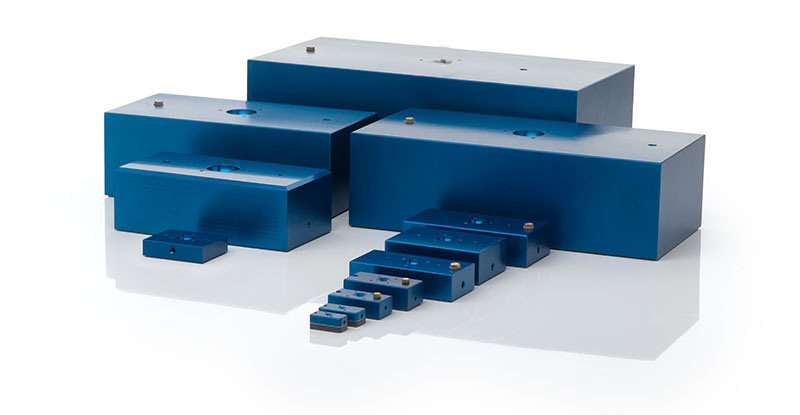

- Flat and Rectangular Air Bearings

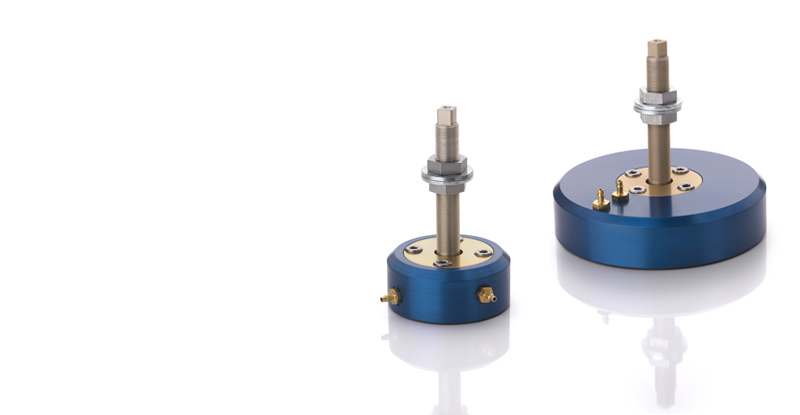

- Air Bushings

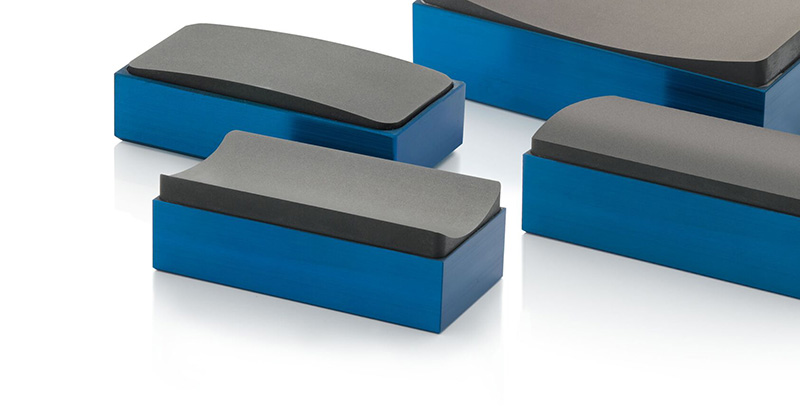

- VPL Air Bearings

- Linear Slides

- Shafts

- Radial Air Bearings

- Clean flat, round, or rectangular air bearing and guide surfaces when needed.

- Clean with 60 psi (0.41 MPa) air pressure applied, using using Isopropyl Alcohol 70% ONLY.

- Do not clean bearing surfaces or guideways with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping surfaces thoroughly.

- Allow the alcohol to evaporate completely from the porous media and guide surfaces before passing bearings over cleansed areas.

- Clean bushing and shaft surfaces when needed.

- Clean with 60 psi (0.41 MPa) air pressure applied, using using Isopropyl Alcohol 70% ONLY.

- Do not clean bearing surfaces or shafts with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping surfaces thoroughly.

- When inserting bushing into the mounting block, take care not to pinch or deform O-rings. Use Isopropyl Alcohol 70% ONLY on O-rings to ease application. Do not allow O-rings to “catch” inside the mounting block. Deformed or damaged O-rings will adversely affect bushing performance.

- After cleaning or insertion into the mounting block, apply 60 psi (0.41 MPa) air pressure and allow alcohol to evaporate completely before using bushings.

- Clean vacuum preloaded air bearings (VPLs) and guide surfaces when needed.

- Clean with 60 psi (0.41 MPa) air pressure applied, using Isopropyl Alcohol 70% ONLY.

- Do not clean VPL bearing surfaces or guideways with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping surfaces thoroughly.

- Allow the alcohol to evaporate completely from the porous media and guide surfaces before passing VPL air bearings over cleansed areas.

- Clean air bearing slide truck and guide surfaces when needed.

- Clean with 60 psi (0.41 MPa) air pressure applied, using Isopropyl Alcohol 70% ONLY.

- Do not clean bearing surfaces or guideways with ketones.

- When removing the slide unit from the rail, the slide must be removed with 60 psi (0.41 MPa) air pressure applied. It is strongly recommended that the slide unit not be removed from the rail. If removed, be sure to reassemble in the same orientation.

- Do not apply the slide unit to any rail other than the one on which it was provided.

- Clean by applying alcohol to a clean, dry cloth and wiping surfaces thoroughly.

- Allow guide surfaces to dry completely before using bearings over cleansed areas.

- Clean shafts thoroughly prior to installing porous carbon media air bushings.

- The protective layer of oil must be completely removed from the shaft prior to the installation of New Way® air bushings.

- Clean with 60 psi (0.41 MPa) air pressure applied, using Isopropyl Alcohol 70% ONLY.

- Do not clean bearing surfaces or shafts with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping guide surfaces thoroughly.

- Allow the alcohol to evaporate completely before passing bushings over cleansed shafts.

- Clean radial air bearings and guide surfaces when needed.

- Clean with 60 psi (0.41 MPa) air pressure applied, using Isopropyl Alcohol 70% ONLY.

- Do not clean radial air bearing surfaces or guideways with ketones.

- Clean by applying alcohol to a clean, dry cloth and wiping surfaces thoroughly.

- Allow the alcohol to evaporate completely from the porous media and guide surfaces before using New Way Radial Air Bearings over cleansed areas.

Air Supply

DO NOT OPERATE NEW WAY® PRODUCTS UNLESS AIR PRESSURE IS APPLIED!

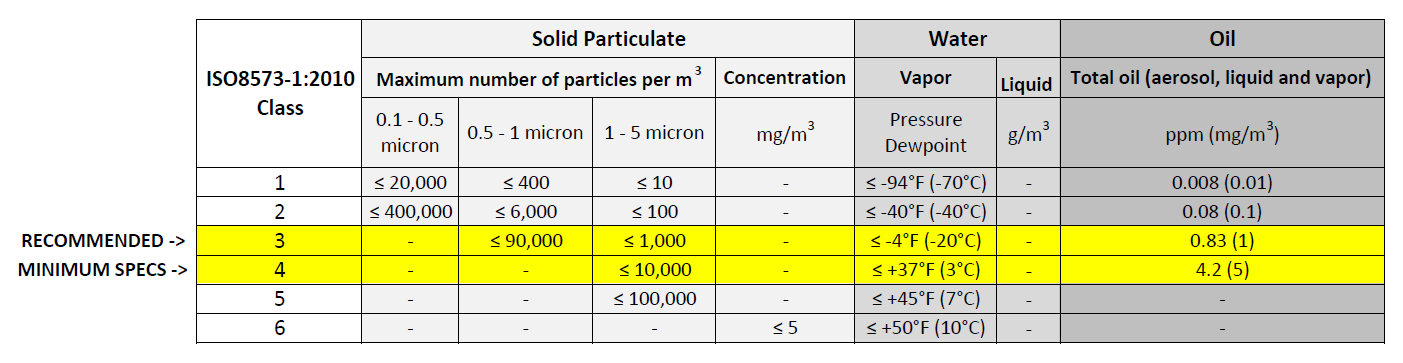

Compressed Air Supply Specifications

Filtering and Drying of Compressed Air

- Air supply must be free of contaminants and moisture (filtered air supply is highly recommended).

- Compressed air used to supply an air bearing must be properly cleaned and dried.

- Air bearing performance and useful lifetime greatly depend on the quality of the compressed air.

- An efficient system ensures minimum pressure loss, removal of contaminants such as water, oil, dirt, rust, and other foreign materials.

- Particles will not affect the performance or life of New Way® Porous Air Bearings, but oil and water will.

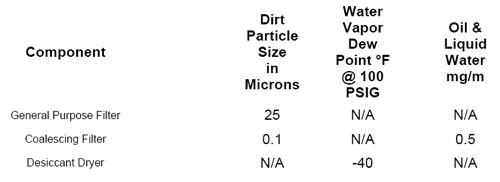

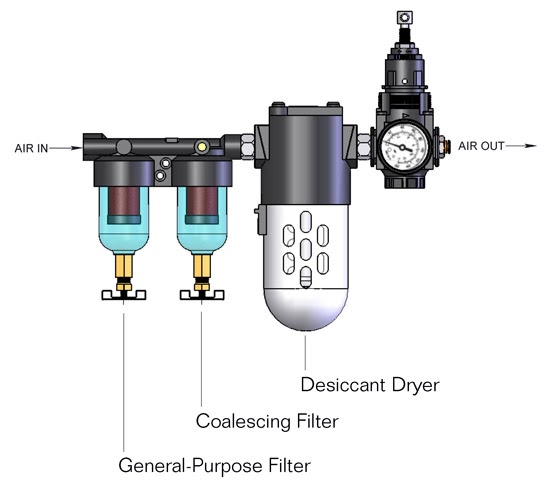

- In order to ensure the specified performance and useful lifetime of the bearings, it is recommended that the following minimum criteria be met:

- General-purpose filters are used to remove the bulk of particles before it gets downstream and damages the coalescing filter.

- The coalescing filter is used to remove oil and liquid water, including all the particles that passed through the general-purpose filter.

- The desiccant dryer is used to remove the water vapor before it condenses.

Cleanroom Applications

New Way® Air Bearings have been verified to satisfy the requirements of ISO 14644-1 Class 3 cleanliness, with airborne particulate concentrate limits of less than 1,000 x 0.1μm particles / m3.

Additionally, the porous media itself acts as a sub-micron filter, so the air flowing out of the bearing is inherently clean, making it plausible for their usage in cleanrooms as clean as Class 1.

More information can be found in our technical report Porous Media Air Bearings for Cleanroom Applications.

Related Attachments

Learn More About the Porous Media Difference