Automobile Testing

Frictionless motion enables rolling wind tunnels and true force dynamometry.

New Way® Air Bearings provides an array of Frictionless Motion®️ solutions to overcome common challenges in vehicle testing. Our Porous Media Technology™ is used in critical component inspection, as well as many Formula 1 wind tunnel testing facilities and dynamic test actuators for automobile testing. But, the applications don’t stop with cars.

Companies have used air bearings to test small motors found in appliances, car windows, and medical equipment. New Way’s air bearing products allow you to finely tune motion to test for vibrations, integrity, torque, and fatigue on your vehicles ensuring your products are up to any challenge.

Contact New Way today to discuss your vehicle testing process.

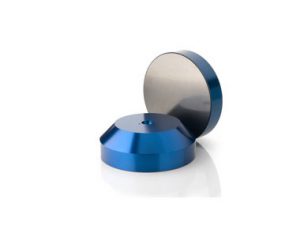

New Way Flat Round Air Bearings are our most popular air bearing. They come in a wide variety of sizes to fit any application and space restrictions. Porous media evenly distributes a thin cushion of air over the entire face of the bearing. Fly heights as small as 5㎛ are easily achievable and accuracy of motion is in the nanometers.

New Way Flat Round Air Bearings are our most popular air bearing. They come in a wide variety of sizes to fit any application and space restrictions. Porous media evenly distributes a thin cushion of air over the entire face of the bearing. Fly heights as small as 5㎛ are easily achievable and accuracy of motion is in the nanometers.

Building off of the success of our Flat Panel Display processing, New Way’s vacuum preloaded air bearings give you unprecedented flatness for your rolling tracks. The combination of air pressure and vacuum allows for fine tuning of the fly heights and keeps your track perfectly flat. This facilitates accurate velocities for precision road tests on any type of vehicle at speeds of up to 80 m/s.

Building off of the success of our Flat Panel Display processing, New Way’s vacuum preloaded air bearings give you unprecedented flatness for your rolling tracks. The combination of air pressure and vacuum allows for fine tuning of the fly heights and keeps your track perfectly flat. This facilitates accurate velocities for precision road tests on any type of vehicle at speeds of up to 80 m/s.

Our radial air bearings provide no contact rotary motion for round components in your vehicle testing process. They come in both concave and convex shapes to ride on the outer or inner diameter depending on your structural requirements. New Way’s radial air bearings have been used in highly precise dynamometer measurements of the speed and torque of an engine’s output power.

Our radial air bearings provide no contact rotary motion for round components in your vehicle testing process. They come in both concave and convex shapes to ride on the outer or inner diameter depending on your structural requirements. New Way’s radial air bearings have been used in highly precise dynamometer measurements of the speed and torque of an engine’s output power.

New Way’s air bushings are constructed with porous media lining the inner diameter of a cylindrical aluminum shell. This creates an even distribution of air that can self-center on shafts that come in both English and Metric sizes. Our air bushings can reproduce accurate road conditions which allow for testing of noise or vibrations in vehicle design. We also offer a wide variety of off the shelf bushings as well as custom options to fit your current application.

New Way’s air bushings are constructed with porous media lining the inner diameter of a cylindrical aluminum shell. This creates an even distribution of air that can self-center on shafts that come in both English and Metric sizes. Our air bushings can reproduce accurate road conditions which allow for testing of noise or vibrations in vehicle design. We also offer a wide variety of off the shelf bushings as well as custom options to fit your current application.

New Way Air Spindles create a stiff uniform layer of air between the rotor and the stator, providing rotary Frictionless Motion®️, ideal for inspecting critical components in the vehicle.

Air spindles can be sold as a stand-alone product, enabling a customer to integrate with their motor/encoder of choice. For customers looking for an integrated solution, New Way also offers Servo-Driven Rotary Stages. Available in several standard sizes, servo-driven rotary stages integrate an air spindle with a high-performing motor/encoder, providing a precise and robust inspection solution in one product.

New Way’s porous media technology has been used in a variety of vehicle testing facilities. Reach out to us today to tell us more about your specific application!

Inspection of components critical to efficient and safe vehicle operations such as:

For constraining and supporting the outer or inner diameter of a rotating assembly.

For unparalleled straightness of motion over metal or stone guideways.

Frictionless motion enables rolling wind tunnels and true force dynamometry.