Aerospace Manufacturing

Whether it be civil or defense, in the atmosphere or hard vacuum, precision motion is crucial to developing these technologies.

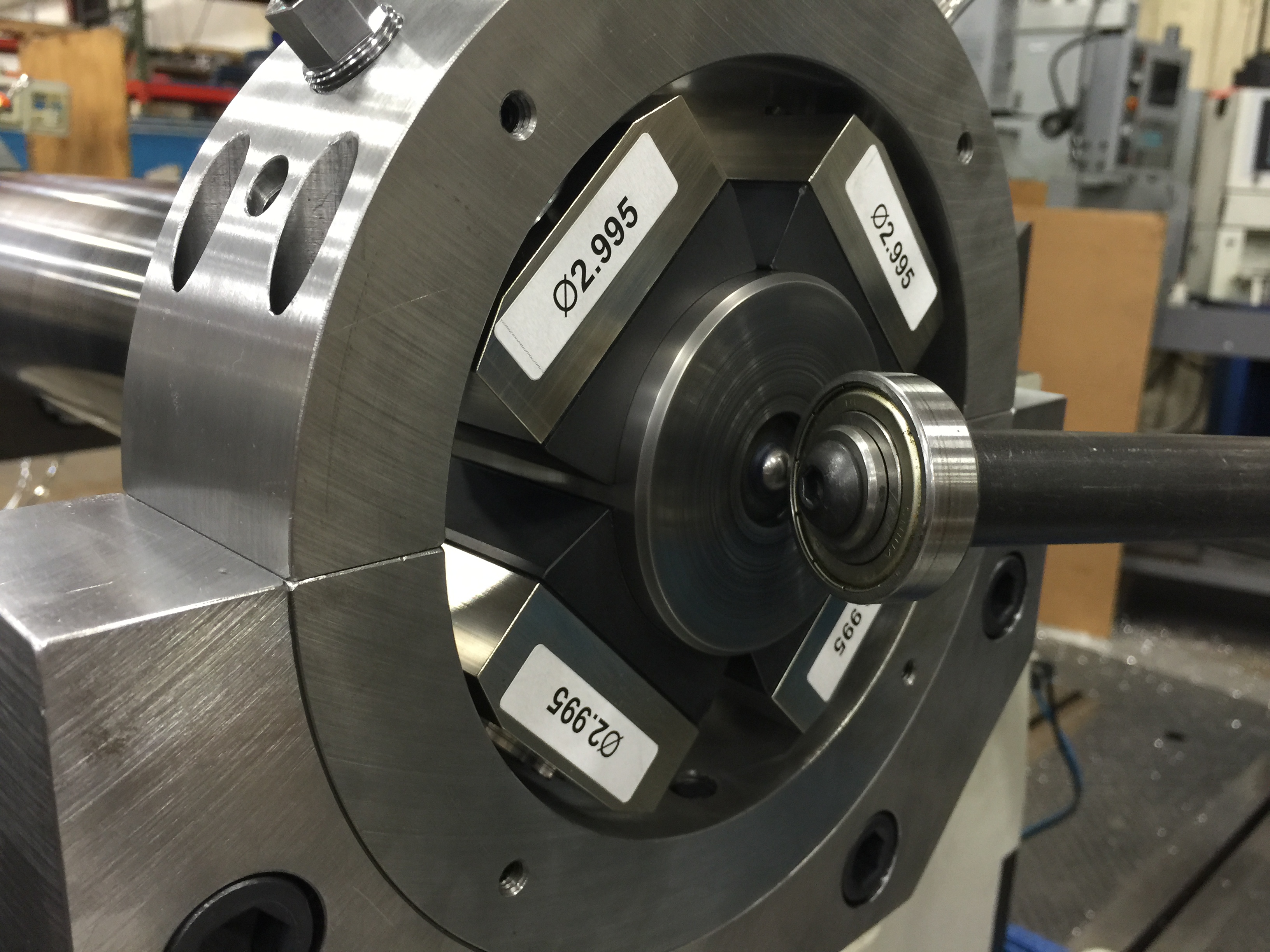

New Way® Air Bearings now offers externally pressurized balance bearings for non-contact support of rotors during balancing operations.

We combine our radial air bearings —which utilize our Porous Media Technology™ —with special adaptive hardware. This eliminates damage to the rotor from contact with hard rollers as well as the mess of oil film bearings in vacuum chambers. Most importantly, the air bearings provide a more precise axis of rotation with a cleaner signal for high-resolution balancing.

Mechanical, electrical, and audible noise in balancing operations is reduced by supporting the rotor on air bearings in both hard and soft balancing machines. When a rotor is supported in rotation by hard rollers, any error motion in the rollers can mask out the balance forces, resulting in unreliable balance measurements.

In typical machines, combined errors from run out of the four supporting rollers cause asynchronous motion errors of the balancing rotor that often exceeds .001 of an inch. Alternatively, with the rotor supported on air bearings, the roundness of the journal (often .0001 of an inch or better) is the only rotating reference surface. The errors in motion will be synchronous, and averaged to less than one-tenth of the amplitude of the hard rollers’ motion errors. This results in a clean signal that is exactly the same each revolution, allowing for a finer resolution in balancing.

In typical machines, combined errors from run out of the four supporting rollers cause asynchronous motion errors of the balancing rotor that often exceeds .001 of an inch. Alternatively, with the rotor supported on air bearings, the roundness of the journal (often .0001 of an inch or better) is the only rotating reference surface. The errors in motion will be synchronous, and averaged to less than one-tenth of the amplitude of the hard rollers’ motion errors. This results in a clean signal that is exactly the same each revolution, allowing for a finer resolution in balancing.

A rotor supported on rollers will also see some axial forces from misalignments of those rollers. Changes in this axial force, say from changes in unbalance force, are likely to be almost synchronous, but out of phase enough to obscure balance resolution. Air bearings impart zero axial force on the rotor, avoiding this error source.

The radial friction is also near zero, so the heavy spot finds the low point of rotation when the air pressure is supplied to the air bearings. This improves the resolution in static balancing by an order of magnitude because the static breakaway coefficient of friction is 10 times lower than that of rolling elements for a typical roller stand or horizontal-way static balancing set-up.

New Way provides “bolt-on” adaptive hardware for integrating air bearings into existing low-speed balance machines.

The adaptive hardware uses the same mounting features as the original hard rollers, and is easily accommodated into your current system. We can also design the bearing pads to “snap on/snap off”, further simplifying the upgrade to your balance machine. This feature allows easy swapping of various sizes of bearing pads, so the balance machine operator can balance rotors without having to adjust or plumb air into the bearings.

The adaptive hardware uses the same mounting features as the original hard rollers, and is easily accommodated into your current system. We can also design the bearing pads to “snap on/snap off”, further simplifying the upgrade to your balance machine. This feature allows easy swapping of various sizes of bearing pads, so the balance machine operator can balance rotors without having to adjust or plumb air into the bearings.

An additional and very practical benefit of replacing the hard rollers with air bearings is that the rotor can be supported on its bearing journals without fear of damage to the bearing surface. This means avoiding issues arising from point contact with a hard roller and from contamination between the rolling surfaces at high speeds. Our balance bearing faces are made of graphite, which presents a large, soft contact area to ensure the rotor remains undamaged in event of contact.

In high speed or “at speed” balancing, the stiffness, and damping function of the support bearings becomes critical for good balancing. This is why large rotors are often balanced on operational hydrodynamic oil bearings, even though these oil bearings can make a mess of the rotor in vacuum or cleanroom environments. This is especially an issue for motors and generators with electrical windings, but oil is still a mess for any bladed roller.

Air bearings eliminate the need to flood, contain, and collect oil in a vacuum, and use so little air that vacuum pressure in the bunker is not affected. Air bearings’ unique, positive relationship between stiffness and damping, provided by their use of the squeeze film effect provides all the benefits of hydrodynamic bearings without the mess.The future of high-powered turbomachinery may be supported entirely on Porous Media air bearings for these exact reasons, per published works by General Electric’s Research Center

If you’re interested in switching to air bearings for your rotor balancing applications, reach out to New Way today to learn more, and review our full lineup of custom balance bearings designed to meet your needs.

Whether it be civil or defense, in the atmosphere or hard vacuum, precision motion is crucial to developing these technologies.

Learn how Porous Media™ air bearings will revolutionize every corner of the bulk powder handling industry.