Linear Motion Bearings

For unparalleled straightness of motion over metal or stone guideways.

At New Way Air Bearings®, we have always prided ourselves on providing Porous Media™ Air Bearing technology to firms on the forefront of advancing their markets. And, now we see the untapped potential for noncontact air bearings in the textiles and composites manufacturing sector.

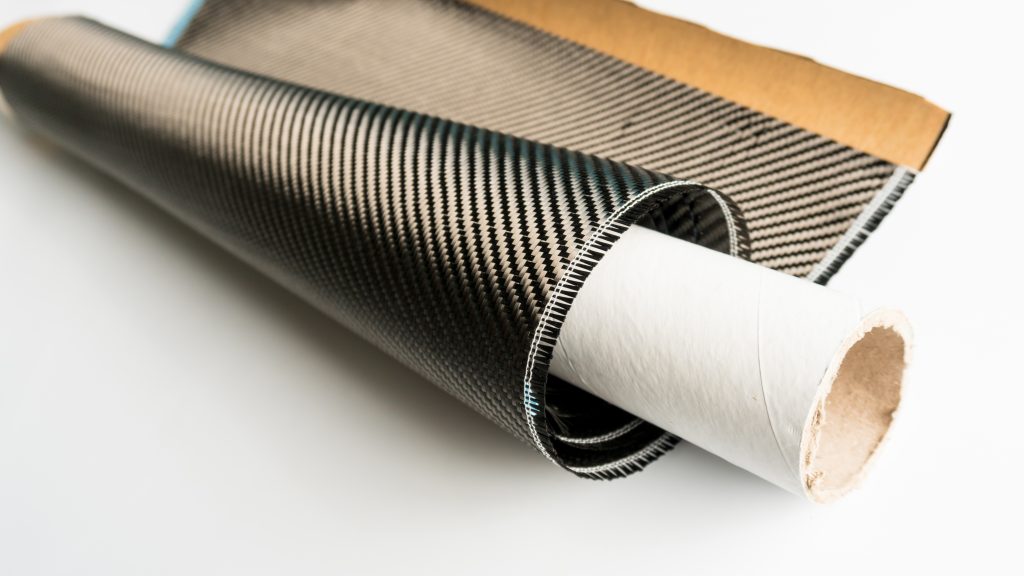

In the 21st century, the textile market doesn’t simply encompass woven fabric for clothing and household goods, but also incredibly high-strength synthetic textiles like carbon fiber, fiberglass, and organic aramids—all of which are spun and woven into their final forms.

The global textile market was estimated at $961 billion dollars in 2019, and by this year, is expected to crest over a trillion dollars annually. A market of this size requires the latest technology to keep manufacturing processes humming along smoothly, as well as providing manufacturing techniques flexible enough to be readily retooled for a new fabric or product design.

The composites market has undergone a meteoritic rise as well. A technology once relegated to niche, mostly aesthetic applications is now a dominant material category for demanding applications with stringent weight and strength requirements.

The composites market has undergone a meteoritic rise as well. A technology once relegated to niche, mostly aesthetic applications is now a dominant material category for demanding applications with stringent weight and strength requirements.

Fiber reinforced polymers like carbon fiber, fiberglass, and aramids form the backbone for airframes, vehicle chassis, and much more, and their anisotropic nature requires far more meticulous processing than materials like steel or aluminum. The alignment of a composite fabric’s weave gives rise to its valuable strength to weight ratio and tensile strength, and ensuring perfection through both manufacturing process and inspection stages is the priority for any composites’ original equipment manufacturer (OEM).

New Way Air Turns™ are a revolutionary application of our porous carbon substrate, allowing for noncontact replacement of traditional contact roller-based systems. Instead of rotating a steel roller using ball bearings, the air turn remains stationary, allowing for up to 180-degree rotation of films and flexible substrates over the Air turn. For the transportation of spread tows and finished fabrics, Air Turns offer a faster, defect-free alternative to traditional rollers.

When producing structurally critical composite components, your non-destructive inspection (NDI) process is as important as your manufacturing techniques, if not more so. Our Flat Round and Flat Rectangular air bearings have a long and successful history of being implemented in XY-gantry configured inspection stages, providing hysteresis-free motion for ensuring part compliance.

Before and during the cure cycle, composites remain delicate, prone to voids, resin pooling, and fiber misalignments which can affect the viability of the finished product. Air Bars, like the Precision Zone series, combine our Externally Pressurized Porous (EPP) Media with vacuum holes, providing for fly height and range control, all while allowing you to transport products at high speeds, safely through your facility.

Because all of our air bearings operate on a 5-micron thin layer of air, there is no contact between the air bearing and its guide surface, and thus, no wear and tear. For suppliers to keep up with the demands of their customers, many production lines run 24/7, and with an air bearing based system, you’ll never find yourself shutting down production for lubrication or a spalled bearing.

Air bearings have become a darling of the metrology and inspection industry for their incredible precision. Because air bearings are a noncontact technology and don’t need to contend with the internal energy of ball bearings, they’re neither susceptible to overshoot or hysteresis error and can be positioned to nanometer levels of accuracy, only limited by the motors which drive them.

One of the main benefits of our Air Turns is their tunable nature. By adjusting the airflow into the bearing surface, you can adjust the fly height of your material, increasing or decreasing tension, and reducing web height variations to <5µm/55mm in the web travel direction and <15µm/200mm in the transverse direction. This report from IBS Precision Engineering details how air turns are ideal for handling even the most delicate substrates with care, saving you the hassle of roller-induced defects, and quickly allowing you to retool for a material with different handling requirements.

New Way Air Bearings are uniquely suited for manufacturing textiles in cleanroom environments and for manufacturers who are especially concerned about potential foreign contaminants entering their products.

Since the air bearing surface acts as a sub-micron filter, the very nature of our air bearings filter air into the environment, and internal New Way testing has demonstrated our products as ISO class 3—and arguably—ISO Class 1 cleanroom compatible.

If you’d like to learn more about air bearings in the textile industry or already have an application in mind, please contact us!

For unparalleled straightness of motion over metal or stone guideways.

Flexible webs can be carried over porous media with minimal stress and strain.