Four Ways Porous Media Air Turns Improve Production Over Orifice Turn Bars

Design engineers in the converting industry are constantly tasked with meeting and exceeding increasing production goals in a wide variety of markets:

- Flat Panel Displays

- Semiconductors

- Solar PV Cells

- Labeling/Printing

- Metrology Equipment

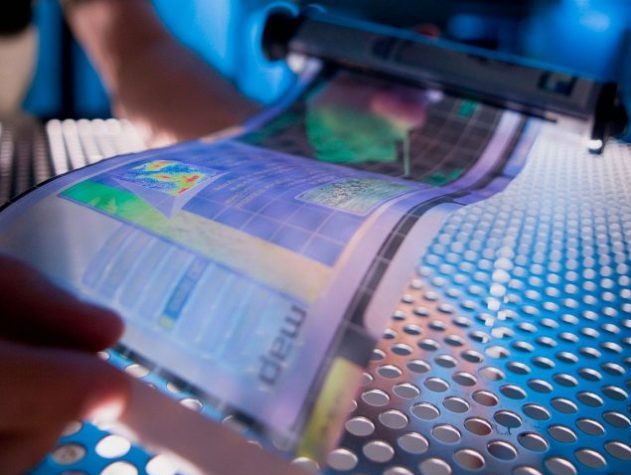

- Printed and Flexible Electronics

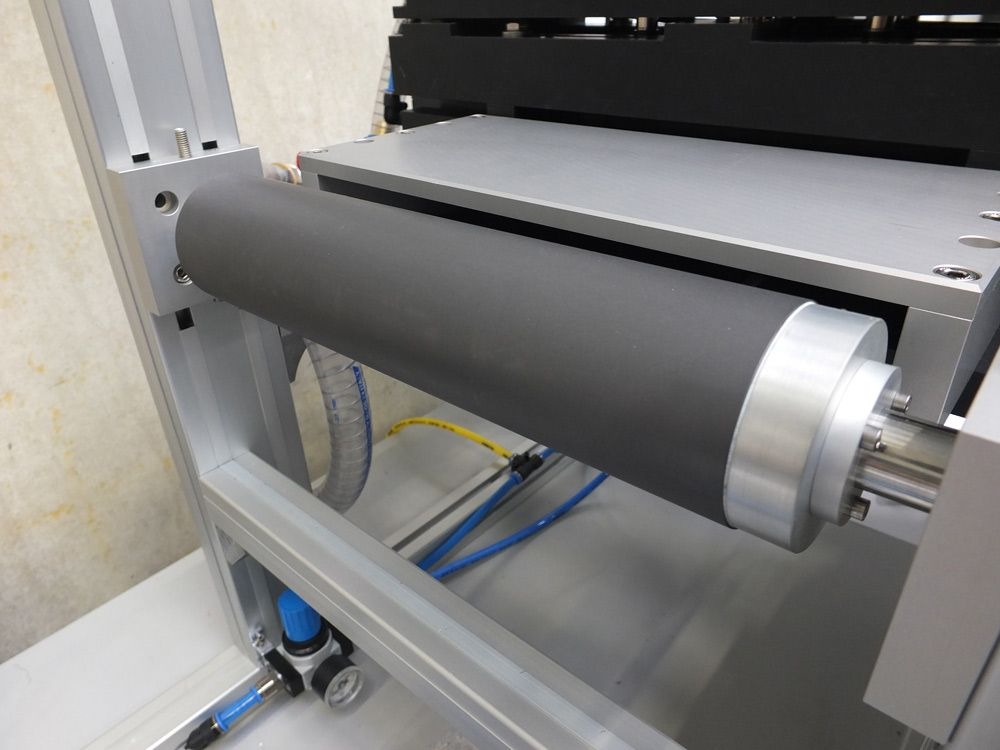

Across many industries, roll-to-roll and web handling processes share many of the same tools—like web turn bars—used to flip films and substrates at a 90-degree angle. While turn bars are an improvement over conventional ‘oiled’ rollers, New Way® Air Turns™ provide a superior alternative solution through the use of our Porous Media Technology™.

Porous Media Air Turns vs. Web Turn Bars: Fundamental Differences in Noncontact Technology

Engineers have long used noncontact solutions to remove the need for oil and lubrication, a common driver of downtime, and reduced production. The use of pressurized air provides the lift necessary to perform the same function as conventional rollers without any of the maintenance requirements or drawbacks.

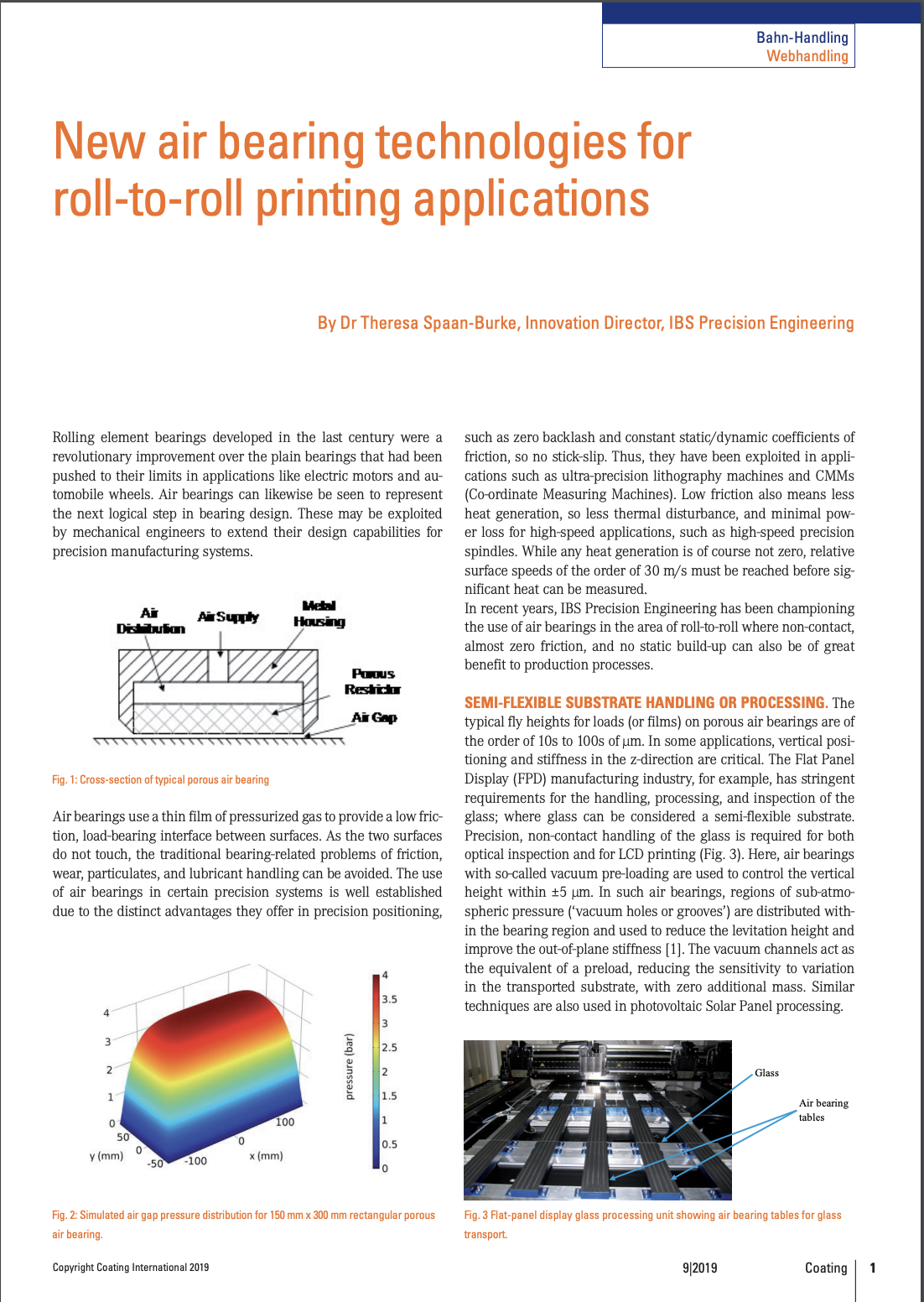

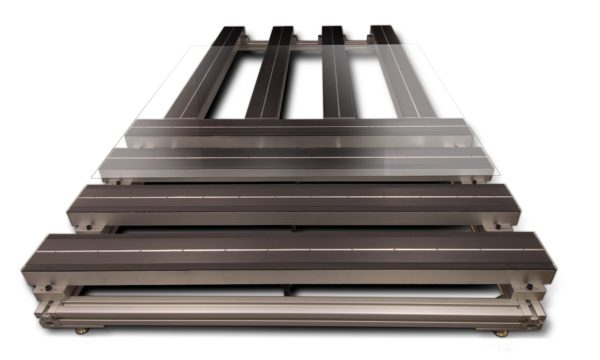

Orifice turn bars represent an outdated form of Frictionless Motion®️, utilizing orifices and grooves to create air pathways, and allow for noncontact motion. Porous media turn bars, built on the air turn, employ Porous Media Technology by distributing air through millions of sub-micron holes, creating an even pressure distribution across the substrate. Part of New Way’s 25-year history of Porous Media Technology has been the use of Air Bars for manufacturing flat-panel displays.

Air bars provide the ability to control the glass and inspection without contact, all while maintaining control via tunable fly heights and vacuum guideways. A logical next step was the creation of air turns as an alternative to support flexible substrates for noncontact web handling and roll-to-roll processes.

Porous Media Technology provides numerous benefits over orifice bearings, which include:

- Long-Term Reliability

- Variable Web Tension

- Even Air Pressure Distribution

- Noncontact Inspection

- Cleanroom Compliance

Four Key Areas Where Air Turns Increase Production

A recent study by the Smithers group indicated that the global packaging market expects to expand 3% per year over the next decade. However, increasing productivity remains the biggest challenge. As a result, in 2017 alone companies planned to invest 24% more resources into equipment over the next year. This investment will be necessary to keep with increased spending for semiconductor equipment, and growing market demand for flexible electronics.

Design engineers across a wide array of industries are investigating options to increase mass production in web handling. Air turns are poised to help meet the increased demand by overcoming four major production challenges compared to the use of turn bars.

1. Increased Reliability

While turn bars have less wear than conventional rollers, their reliability is still sub-par when compared to air turns. Because of their orifice design, turn bars need to have a larger air gap in order to prevent a costly collapse due to restricted airflow.

Because airflow to an air turn passes through millions of sub-micron holes, there is no potential for collapse and no dynamic components that can fail. This is far superior to conventional rollers, which often necessitate a production halt so they can be lubricated.

2. Noncontact Inspection

You can have great productivity, but if the processes and mechanisms don’t allow for regular inspection, then you won’t be catching any defects until the end of your manufacturing cycle. This can potentially result in tens of thousands of dollars down the drain.

Porous media turn bars offer the unique capability of in-situ inspection. This allows you to make use of the air film your material rides on to support non-intrusive, interferometry-based inspection stages while your material is still in process.

This technology has already been proven by IBS Precision Engineering and found that an air table produced a maximum web variation of 6µm, compared to 100µm without an air barrier.

3. Roller Contamination and Defect Reduction

While orifice based turn bars provide a noncontact solution, their design inherently sets them up for potential contamination since the air is not distributed evenly. Turn bars can have pressure gradients causing the web to sag, bow, and potentially contact the turn bar, resulting in wasted product or even replacement of the turn bar.

Air turns provide an even distribution of air, eliminating the pressure gradients. That means no more contamination concerns for your process. Furthermore, New Way has pioneered the use of directional control bearings on the air turn, allowing for variable web tension.

The air turn is capable of fly-height thicknesses between 100 and 600µm, and web tension up to 200N. As a result, no matter the material or substrate, the air turn can compensate and ensure material flatness. This same process has been utilized by New Way’s T-Series and H-Series air bars for flat-panel displays to great effect.

4. Cleanroom Compliance

More and more, industries are mandating cleanroom conditions for their manufacturing processes, and in the electronics and semiconductor fields, it is an absolute necessity. As flexible electronics take shape and start to reach the consumer market, manufacturing methods will need to keep pace and ensure that quality doesn’t suffer.

More and more, industries are mandating cleanroom conditions for their manufacturing processes, and in the electronics and semiconductor fields, it is an absolute necessity. As flexible electronics take shape and start to reach the consumer market, manufacturing methods will need to keep pace and ensure that quality doesn’t suffer.

As much as air bars furthered the conveyance flat-panel displays, air turns will do the same for flexible films, all without compromising the cleanroom. A traditional contact turn bar can impart defects onto a surface. Along with their need for lubrication, this makes contact turn bars incompatible with cleanroom conditions.

While an orifice-based solution might be better, the size of its grooves allows for particle infiltration. New Way recently showed that our air bearing products are ISO 146441-1 Class 3 Cleanroom Compliant. For comparison, the Porous Media Technology in New Way Air Turns has a host of benefits:

- Acts as a sub-micron air filter

- Prevents virtually any particle intrusion into the environment

- Dries out saturated material

These four areas have a significant impact on overall production, including quality, which—in turn—affects your bottom line. When deciding to use air turns or turn bars, air turns are a superior choice, offering consistent performance and production.

Beyond Turn Bars: The Versatility of Air Turns

While Porous Media air turns provide an alternative to conventional turn bars in roll-to-roll processes, they can also be extended to replace other components. Increased reliability, reduced defects, and eliminated contamination doesn’t just apply to turn bars. Here are some other components that can be upgraded with Porous Media:

- Roller Bars

Air turns provide a zero-contact solution to replace rollers where friction is a problem. Contamination concerns are eliminated, maintenance is significantly reduced, and overall production performance benefits.

- Spreader Bars

The even distribution face of air turns enables them to remove wrinkles from a flexible web with zero contact. Furthermore, the tunable nature of air turns allows you to adjust web tension as needed for high-speed production. This eliminates wear and increases reliability, all while resolving contamination concerns and straightening the web.

- Tension Bars

Air turns can apply tension to a web without having to physically reposition, minimizing complexity. This reduces the potential for machine wear and contamination issues.

Ready to Turn Up Your Production?

Whether you are considering a replacement for turn bars or other rollers/bars, New Way Air Turns can help you meet production demands. From the semiconductor industry and flexible electronics to basic packaging, air turns can be used to manufacture an extensive range of products.

We’re ready to show you how air turns can be used to increase production for your project. Download our roll-to-roll processing eBook to learn how your custom application can benefit. Or, contact us today for a complimentary consultation to learn how air turns can increase your bottom line!