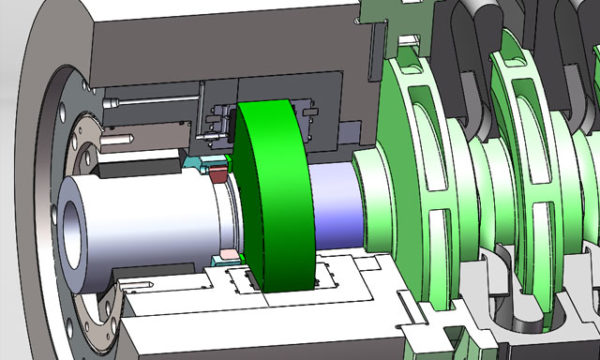

Fluid-induced instability, known as whirl and whip, has long been a challenge in the field of rotor dynamics. However, a groundbreaking solution has emerged in the form of externally pressurized bearings and seals. This technology, pioneered by Don Bently, offers a revolutionary approach to eliminate both whirl and whip, providing a stable and…

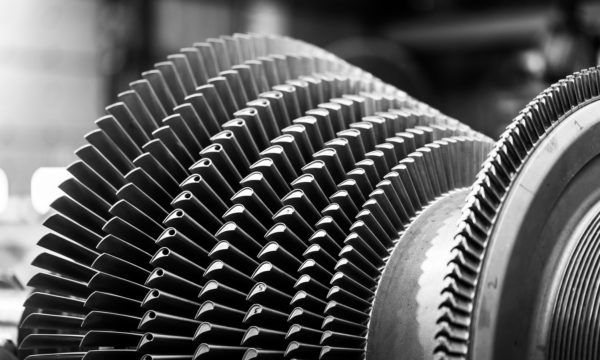

How Do Air Bearings Compare to Existing Turbomachinery Bearings?

At New Way Air Bearings ®, we remain committed to continuous innovation in the field of porous media air bearings, both in advancing our own technologies and its applications to new industries. Today we want to highlight the innumerable benefits porous media offers to the turbomachinery sector, backed up by the work of our founder,…

Learn How Air Bearings Mitigate Turbomachinery Resonance

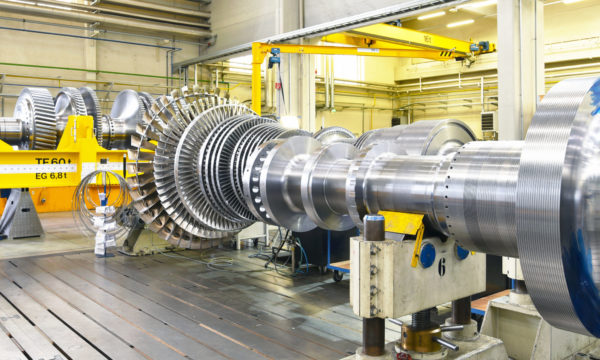

New Way Air Bearings® offers non-contact technology for the support of turbomachinery applications.

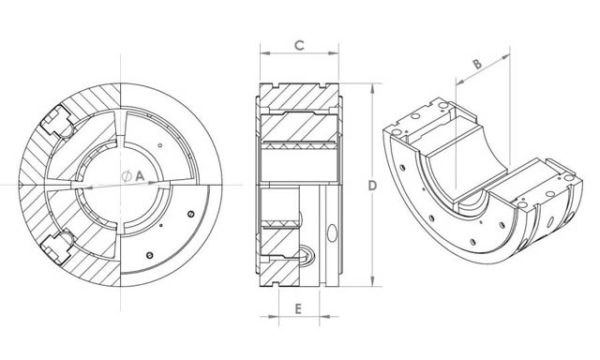

Comparing Precision Radial Bearings: Geared for the Turbomachinery Industry

5 Reasons to Consider Precision Radial Gas Bearings from New Way As with any industry, the search for simpler and lower maintenance solutions is an ongoing pursuit to improve the bottom line. The turbomachinery industry is no exception. Tilt pad bearings are often used in these applications for their ability to operate at high speeds;…

Bearings Cost Calculator

See Your Bearing SavingsBetter Seals: Advancements in Turbomachinery

New Way’s Technology for Your Own Advancements in Turbomachinery Equipment downtime is a multi-billion dollar problem in the powder and bulk industry. Equipment safety concerns often go hand-in-hand. The issue is not a lack of predictive or preventive maintenance. Rather, the problem is inherent in the design of the turbomachinery itself. Shaft seals, in particular,…

Revolutionizing Oil and Gas with Bently Bearings for Turbomachinery

Proven Technology De-Risks These Bearings for Turbomachinery Applications Yes, it takes a truly revolutionary technology to solve the innumerable issues inherent in the turbomachinery of the oil and gas industry. What is the most debilitating problem for rotating equipment today? Well, that’s debatable. But downtime, operational performance, and safety are the leading candidates. And all…

Bringing Proven Bearing and Seal Technology to Turbomachinery

Applying Proven Bearing and Seal Technology to Turbomachinery Reduces Risk Demanding turbomachinery environments drive the industry and its regulators toward more stringent operational and emissions requirements. Conventional bearings and seals are subject to wear, performance, safety and downtime issues. “For years, the turbomachinery industry has been searching for a new bearing and seal technology which…

Contact us today for a complimentary consultation