5 Reasons to Consider Precision Radial Gas Bearings from New Way

As with any industry, the search for simpler and lower maintenance solutions is an ongoing pursuit to improve the bottom line. The turbomachinery industry is no exception. Tilt pad bearings are often used in these applications for their ability to operate at high speeds; however as with any lubrication-based system, maintenance due to wear caused by friction must always be factored into the ability to meet production goals. New WayⓇ offers an alternative to minimize maintenance with a non-contact solution. New Way’s precision radial bearings provide a frictionless solution through its keystone Porous Media TechnologyTM, utilizing pressurized air or gas to ensure consistent performance every time.

Forging a New Way Ahead in Precision Radial Bearings

New Way has been manufacturing air bearings for the machine tool, semiconductor and wafer manufacturing, and medical industries for 25 years. Recognizing the need for Frictionless Motion®️ in the turbomachine industry, we developed a solution, leveraging our porous media technology we pioneered for linear usage, and placing it along the outer diameter of a curves surface. The result is our radial bearings and balance bearings, ideal for supporting a rotating artifact in such applications as:

- Compressors

- Steam & Gas turbines

- Turboexpanders

- Pumps

- Motors

5 Advantages of New Way’s Radial Gas Bearings versus Tilt Pad Bearings

Tilt pad bearings are prominent in the turbomachinery industry because of their ability to operate at high speeds without causing whirl in certain configurations. While they are able to meet rigorous operating requirements demanded by the turbo industry, this comes at a cost in maintenance and complexity, ultimately affecting profits. Let’s look at five areas where New Way’s radial bearings for turbomachinery are able to overcome obstacles inherent to the tilt pad bearing design.

1. Zero Friction

Friction plagues engineers because of its effect on equipment life, precision, speed, and the oil /lubrication requirements it demands. Tilt pad bearings require oil lubrication systems to manage friction during operations.

In addition to zero friction during operation, radial air bearings use of an external supply of gas that provides zero friction at start/stop, a known deficiency with tilt pad bearings.

2. Precision

Tilt pad bearings require careful design of a series of typically three to six curved pads, each of which can move around a pivot, line, or point. The clearance between the pad and the shaft must be understood and monitored to achieve the desired precision level. This requires complex monitoring software factoring in the number of pads, pre-load, pivot offset, and the direction of the load. The sheer number of components to consider make nano-precision accuracy cumbersome and challenging to achieve.

New Way’s Porous Media’s sub-micron holes allow for even distribution of air across a single face, simplifying attainment of the desired accuracy, as compared to tilt pad bearings. This fact, coupled with zero friction (including start/stop,) allow porous media bearings to operate to nano-precision positioning consistently, making it more reliable and precise. This is a key discriminator of Externally Pressurized Porous (EPP) Gas Bearing Technology in meeting the demand for increased precision of radial bearings in the turbomachine industry/

3. Wear

While lubrication minimizes friction, it cannot completely eliminate it, particularly at start/stop where contact is made. As a result, lubrication-based bearings like tilt pads, experience wear, eventually resulting in maintenance downtime.

The use of EPP Technology in radial bearings equates to no moving parts and no contact (even at start/stop.) The end result is consistent performance and less maintenance, yielding greater production.

4. Speed

For tilt pad bearings, speed is yet another item to consider in its complicated monitoring software. A change in speed must consider the impacts on other aspects of the system (e.g. movement of pads, temperature implications, etc.)

While tilt pad bearings are known for their ability to operate at high speeds, porous media air bearings are also capable of operating at high speeds, yet with a simpler methodology. Given there is no contact and no moving parts, the EPP Technology in New Way products offers a straightforward approach to reaching comparable high speeds.

5. Heat Generation

Heat generation can induce wear and impact operations requiring maintenance downtime. One of the disadvantages of tilt pad bearings is the heat generation created as a result of the sheer number of moving pieces, directly impacting the viscosity of the oil lubricant. This thermal relationship is another factor in the complex equations required to operate tilt pad bearings to meet the desired performance. In some instances, costly cooling systems are required.

Porous media bearings inherently have less heat generation since there are fewer moving components. EPP Technology creates gas across an even porous surface as compared to oil across multiple moving surfaces affected by heat and viscosity changes. While a thermal relationship still needs to be monitored, it is greatly simplified. An external pressure supply allows the input pressure to easily be modified to create a gap, affecting the temperature, if necessary. Our bearings minimize heat generation and provide streamlined methods for managing temperature changes, resulting in less maintenance downtime and longevity of operating equipment.

Choosing your Radial Air Bearing

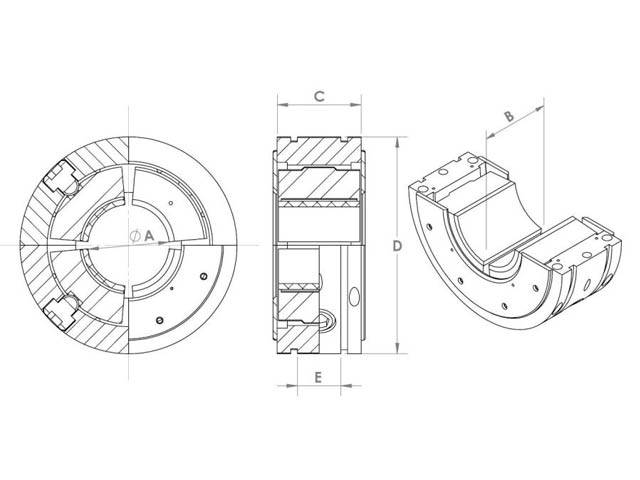

New Way provides a range of precision radial bearings in varying sizes, as well as custom solutions. In addition to radial bearings, we also manufacture thrust bearings for axial/thrust loads which can be used as an alternative to tilt pad oil bearings. A special subset of our radial bearings are the balance bearings. Hard or soft mount compatible, the Balance Bearings balance shafts without contacting hard rollers. New Way’s design improves rotor-balancing through proven EPP Technology. Don’t worry if you aren’t designing from scratch! Balance Bearings can be retrofitted to existing machinery.

Geared Up to Take the Next Step?

If you’re ready to join us in moving the turbomachinery industry forward, contact us today for your complimentary consultation!