Fluid-induced instability, known as whirl and whip, has long been a challenge in the field of rotor dynamics. However, a groundbreaking solution has emerged in the form of externally pressurized bearings and seals. This technology, pioneered by Don Bently, offers a revolutionary approach to eliminate both whirl and whip, providing a stable and efficient operation for machines.

Key Points:

- Understanding Fluid-Induced Instability:

- Fluid-induced instability occurs when a fluid is trapped between two rotating cylinders, causing vibration and potential damage to the rotor system.

- Whirl and whip are two forms of fluid-induced instability, with whip being particularly challenging to address.

- The Bently-Muszynska Threshold of Instability is a critical parameter that determines the stability of the rotor system.

- Controlling Lambda and Stiffness:

- The Threshold of Instability can be raised by reducing the fluid circulation (lambda) through bearing or seal design modifications.

- Increasing the rotor system spring stiffness (K) can also eliminate fluid-induced instability.

- Externally Pressurized Bearings and Seals:

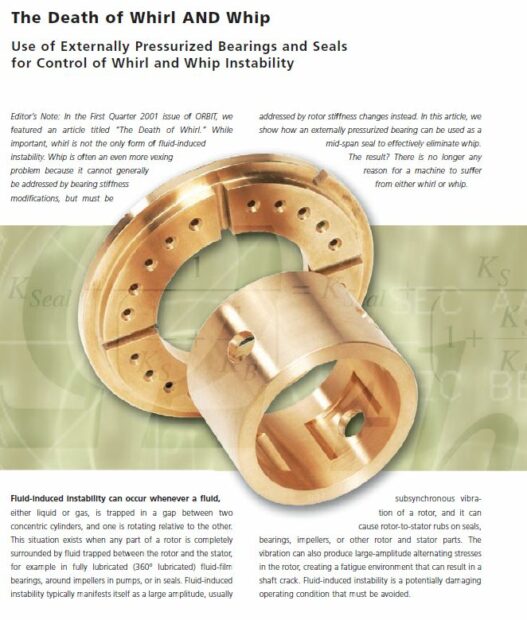

- Externally pressurized bearings and seals operate in a fully lubricated condition, providing variable stiffness control.

- By increasing the pressure and stiffness of externally pressurized bearings, whirl can be eliminated.

- Whip can be addressed by adding an additional spring through pressurizing a seal at or near the midspan of the rotor shaft.

- Advantages of Externally Pressurized Bearing Technology:

- Externally pressurized bearings and seals offer a range of technical advantages, including the ability to inject fluid tangentially to reduce swirl.

- This technology can replace other bearing types, such as magnetic and rolling element bearings, overcoming their disadvantages.

- It allows for variable stiffness control, use of different working fluids, and operation at slow rotational speeds.

Conclusion: The use of externally pressurized bearings and seals represents a significant breakthrough in the field of rotor dynamics. By eliminating both whirl and whip, this technology ensures stable and efficient machine operation. With its numerous advantages and ability to overcome the limitations of other bearing types, externally pressurized bearing technology is poised to revolutionize the industry.

Note: The information provided in this blog summary is based on the document provided and knowledge of the topic. Below you can find the original linked article: