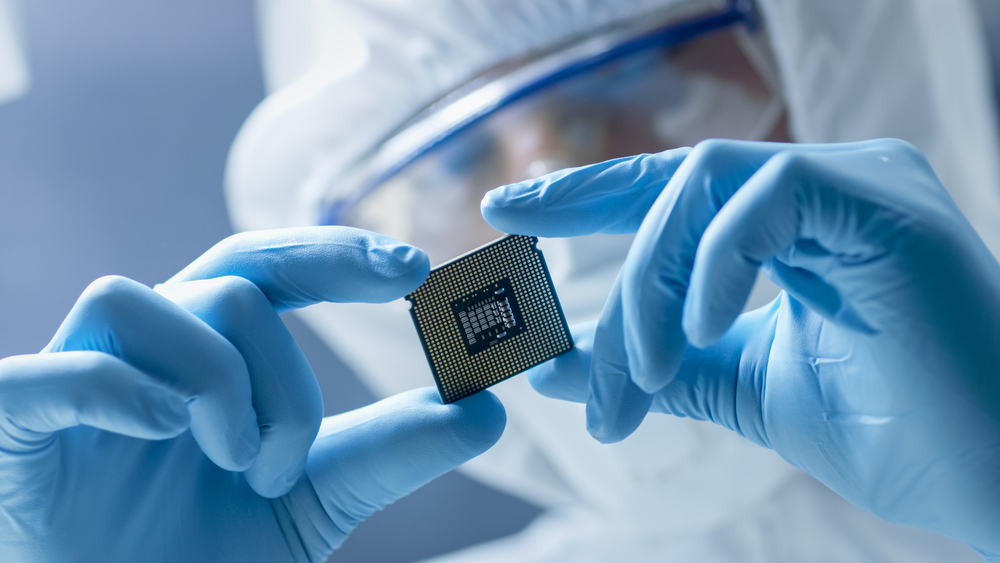

During the height of the Covid-19 pandemic, the world saw unprecedented shortages of many critical supplies . Of all of these, perhaps the most impactful to the global economy has been semiconductors chips. These chips are enormously important, with the products they control touching almost every aspect of our daily lives. While the shortage of semiconductor chips appears to be easing as supply chains open up, it is worth diving into the changes the industry can make so as to avoid these bottlenecks in the future, and create faster, more reliant systems in the process.

The Importance of Air Bearings to Semiconductor Manufacturing

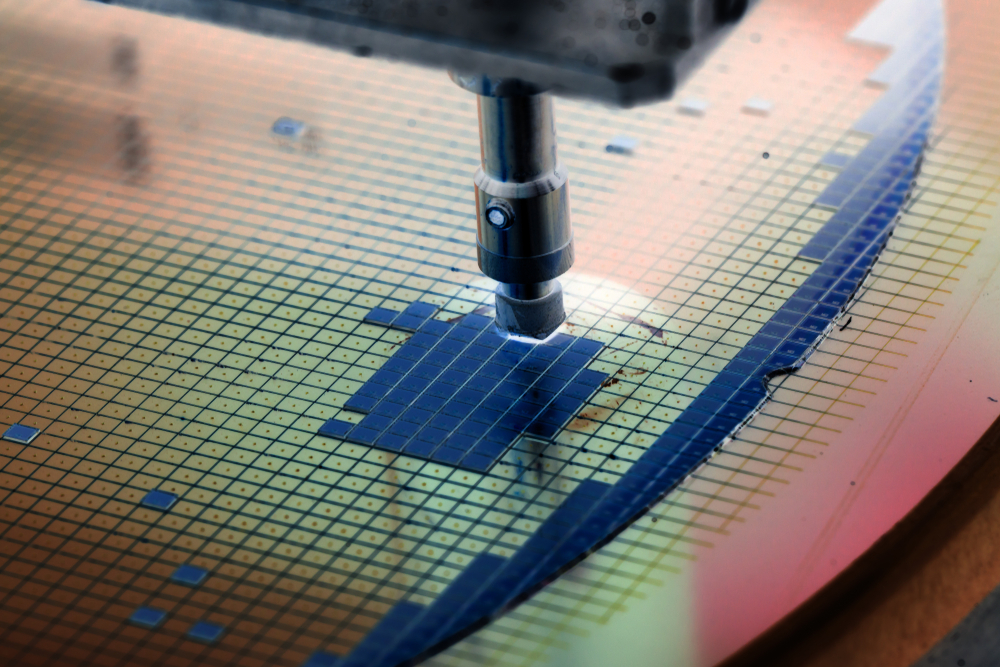

Air bearings are not simply a hypothetical addition to the world of semiconductor manufacturing but already a well established, critical component in the process. ASML, the world leader and sole manufacturer of EUV lithography systems, uses precision air bearings to position prepared wafers for lithography and etching operations. Only air bearings are up to this task, since “we are talking about nanometer scale features with exceptionally small tolerances”, says Fred Huizinga, group leader for mechanical analysis at ASML. The higher stiffness, thermal isolation and lack of particulate ejection of air bearings into the environment are all cited as properties critical to the success of EUV chip manufacturing. Air bearings are so critical to the success of cutting edge semiconductor manufacturing, New Way Air Bearings founder Drew Devitt himself holds a patent on the integration of air bearings into vacuum chambers.

The Next Phase of Semiconductor Chip Manufacturing

In order to keep foundries running smoothly well into the future, manufacturers will need to be able to increase the speed of their processes while maintaining precision and cleanliness. The biggest obstacles to increasing this speed are the limitations of traditional motion systems. New Way® Air Bearings avoids the limitations of older machines by utilizing a porous graphite substrate to create a nanometer-thick stiff air cushion, providing unprecedented speed, precision, and cleanliness.

Precision

Unlike roller bearings, air bearings have no resolution limitations, allowing them to be perfectly positioned every time. They also eliminate the hysteresis error inherent to roller bearings (as discussed in depth in Technical Report 3), delivering perfect accuracy with every motion. Even vibration is eliminated with air bearings, creating an unparalleled platform for precision motion. When cutting, inspecting, or installing semiconductors, the slightest motion can destroy months of work. Porous Media Technology allows these procedures to be completed faster and with enhanced confidence.

Cleanliness

Given the molecular scale of semiconductor production, molecules smaller than a virus can interfere with the miles of circuitry that make up a chip. Porous Media Technology™ addresses this need in its very design. Utilizing millions of sub-micron holes, the substrate acts as its own air filter and cleaner, meeting the Class 1 (ISO class 3) cleanliness required in semiconductor factories.

Porous media bearings are also capable of running at incredibly low pressure, avoiding the potential for interference that orifice air bearings might present. And, as a zero-contact device, the Porous Media air bearing requires no lubrication. This eliminates both the contamination risk of lubricant, and the need for constant maintenance, providing a superior platform for semiconductor chip production. Without lubricants to worry about, you don’t have to consider another source of particulate matter being introduced into a cleanroom environment.

Speed

Similar to the air bearings which ASML uses for wafer positioning, New Way offers numerous solutions to enhance precision conveyance systems. For example, our precision zone air bars utilize vacuum zones in combination with the stiff air cushion to provide the safest, most secure conveyance available, simultaneously ensuring the substrate remains flat against the surface it floats over..

Porous media bearings are also crash-resistant, slowly decompressing in the event of catastrophic failure. This allows all movement to take place at faster rates with reduced risk, enhancing production speed. Porous graphite even retains its stiff air cushion when scratched or damaged, and is soft relative to a guideway, acting as an ablative surface. Independent testing demonstrates that New Way bearings still operate without diminished performance, even after 50 simulated crashes.

How Will Your Industry Benefit?

If you want to learn more about the power of porous media air bearings for the semiconductor industry, read our recent blog post on how linear slides can revolutionize lithography operations, or download our comprehensive Air Bearings for Semiconductors E-Book! If you have further questions or already have an application in mind, please contact us, and our dedicated engineering team will get back to you!