New Way Air Bearings® has always been at the forefront of precision motion technology, and metrology is our oldest application. Our Porous Media Technology™ was developed and refined in order to provide precise, hysteresis-free motion. Over time, this has led to strong and continuous partnerships with metrology OEMs, with many components designed for their particular need.

Our very first application was the use of our flat round air bearings to retrofit Checkmate Coordinate Measuring (CMM) machines. Now we want to cover the breadth of metrology applications air bearings are applicable to, and those they will be needed for in the future.

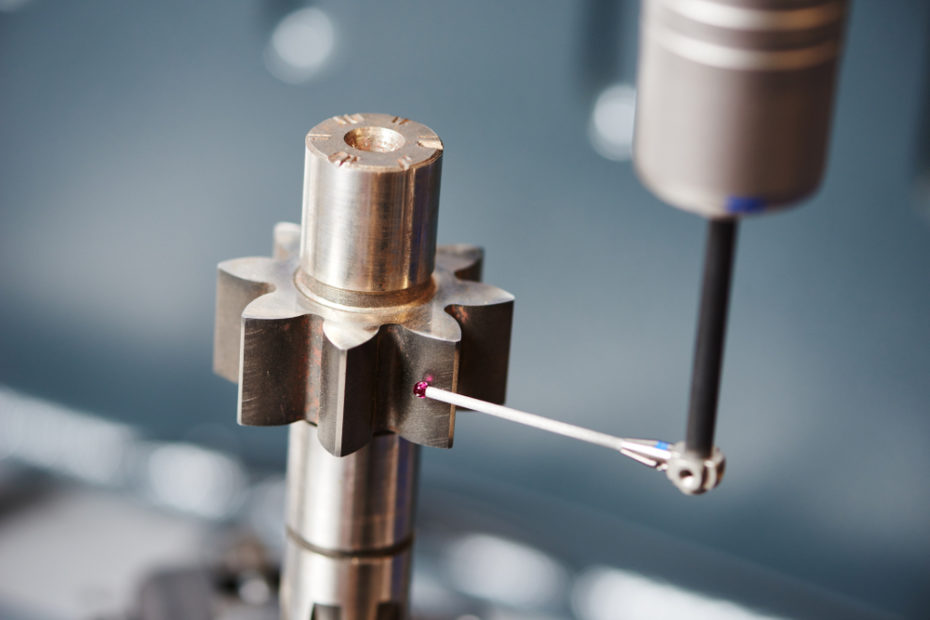

Coordinate verification

Coordinate verification is an increasingly essential metrology technique, ensuring your final product aligns with your digital master file. Checkmate coordinate measuring machines, now a subsidiary of Hexagon, were the first to use our Porous Media bearings. The use of New Way components helped solidify their place as an industry leader.

The hysteresis free-motion of our flat round air bearings allows for precise, nanoscale measurement, a technological feature independently demonstrated by MIT researchers in our Technical Report 3. These bearings are easily configured to form XY gantries, and in the event of total power loss, will softly set down, preserving the guideway surface.

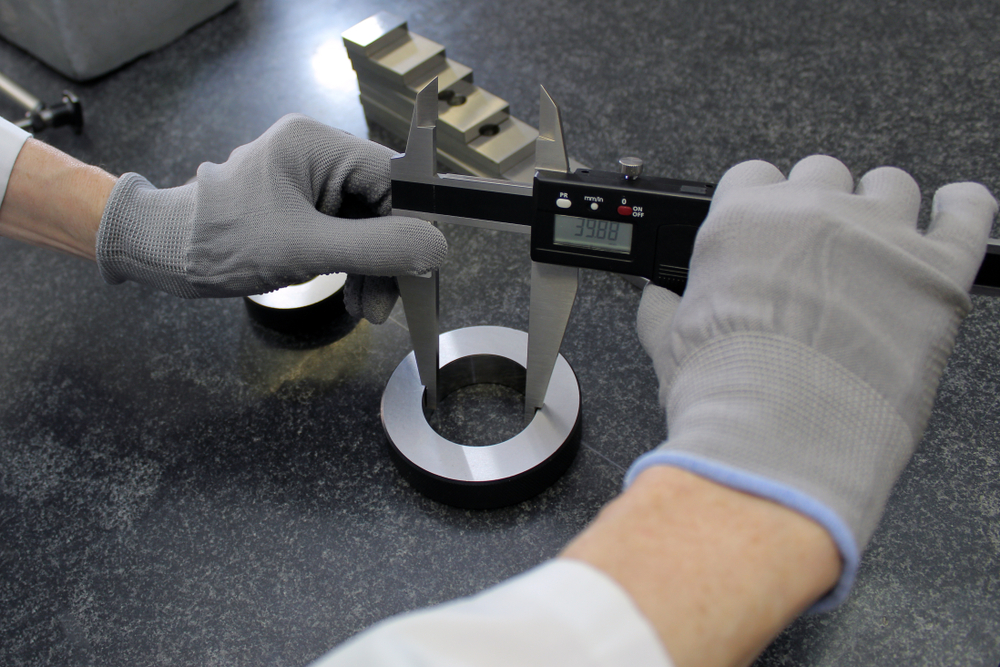

Roundness Checking

Roundness checking machines measure a test article for roundness and cylindricity. For these systems, the test article must be perfectly leveled, and a high degree of rotational fidelity is required to collect data points. For applications such as these, air bearings excel at creating an adjustable Z-axis platen with high repeatability. The nanometer scale precision which air bearings provide along a linear axis extends equally well to rotary motion.

Products like our air bushings, thrust bearings and radial air bearings all enable high speed, highly accurate motion. This isn’t just in theory, either. We’ve already taken advantage of the incredible rotary precision conferred by non-contact motion to produce our Servo-Driven Rotary Stage; an all in one solution for rotary motion.

By combining an air spindle with a brushless, slotless motor and a rotary encoder, we create a motion platform capable of 1.1 arcsecond precision. This technology has already been fielded to position the Keck Observatory, and is equally applicable to roundness checking.

Flatness Control

Flatness control of flexible materials and substrates can be a challenge when using conventional roller bearing systems, but our Air Turns make this a breeze. Because the material is traveling over a film of air, active control of fly height allows you to adjust web tension in real time. Additionally, the resulting air gap below the substrate opens the door to in-situ measurements techniques.

IBS Precision Engineering, a long time partner of ours in the metrology ecosystem, developed ARINNA (Areal Interferometry for Nanoscale Surfaces), a real time interferometry technique for evaluating web stability. Not only an achievement in itself, the project demonstrated that an Air Turn-stabilized film has only a 6µm variation in web height, while a traditional system exhibits variation around 100µm.

Shaft Balancing

Rotor and Shaft balancing is a critical metrology practice for the turbomachinery and marine markets, ensuring a rotor is precisely balanced and rotates about its center of mass. Traditional supporting rollers for rotor balancing can cause asynchronous errors, and the error motion will result in unreliable measurements.

New Way offers bolt-on solutions for shaft balancing through our balance bearings, giving you the ability to easily change your balancing rig for different sized shafts with ease. With air bearings, the rotor, shaft, or journal is the only rotating reference surface. As such, all motion error is averaged, providing a clean signal for finer resolution. Additionally, axial forces owing to misalignment of roller bearings are removed.

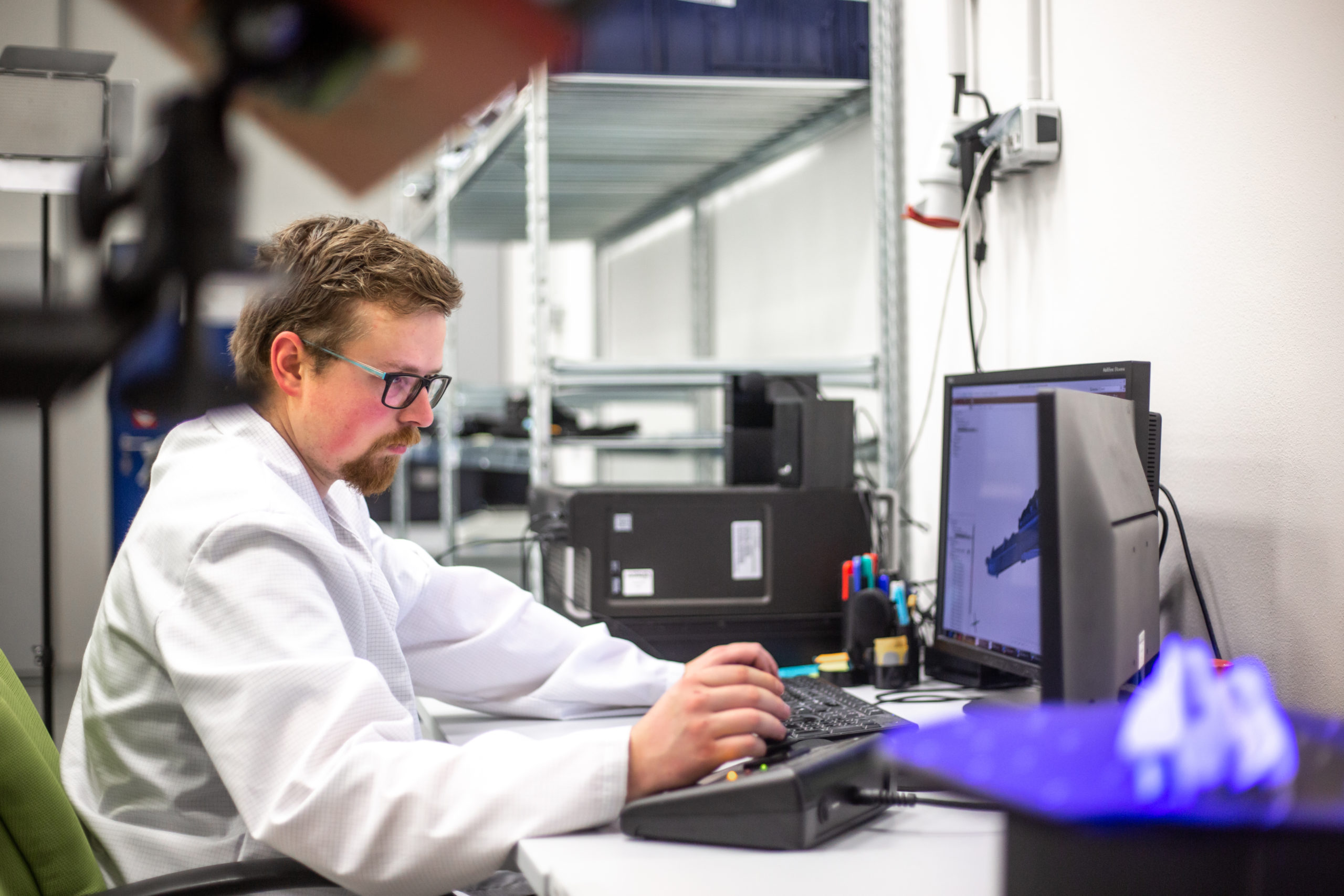

Metrology Retrofitting

Retrofitting your system to take advantage of the latest trends can seem intimidating, but New Way makes it easy. Not only were our air bearings first used in CMM’s, but so was the first use of our air bearings to retrofit a system.

From these beginnings, we’ve developed an entire catalog of drop-in ready retrofit bearings for Sheffield Coordinate Measuring Machines, allowing you to cross reference your make and model. This lets you easily know not only which bearings you need, but how many.

If your metrology system is from a different OEM, we’re also experienced in producing custom retrofit bearings. Our in-house engineering team can design to meet your specifications, and will work with the OEM (as we’ve done with Cannon) to facilitate a safe, approved retrofit process.

Contact Us

Want to learn more about what Porous Media air bearings can do for metrology, or do you already have an application in mind? Contact us today to get started!