All eyes are on the medical industry these days. As the world grapples with the coronavirus global pandemic, we are reminded of our reliance on healthcare professionals, including the tests, devices, and diagnostic tools available to them. Healthcare breakthroughs of the last decade are helping to address the medical industry’s increasing demands for:

- Diagnostic tests such as computed tomography (CT or CAT scans)

- Medical devices from hearing aids to pacemakers

- Artificial limbs/organs

- ‘Smart’ diagnostic devices for screening and monitoring

Despite this broad spectrum of needs, some common themes begin to appear in the form of unprecedented requirements being driven on manufacturers and medical suppliers, such as:

- Precision

- Accuracy

- Repeatability

Receiving requirements like these force many medical manufacturers and suppliers to revisit the capabilities of all components, including the type of bearing being used in production and operation.

It’s also why New Way® is seeing increased use of air bearings within the medical industry. Let’s look at a few of the benefits of air bearings for the medical industry.

Five Benefits of Air Bearings For The Medical Industry

With the enhanced precision being driven on the various aspects of the medical industry, manufacturers look to the prime suspect for errors—friction—in particular.

Eliminating friction not only enhances precision but also removes the side-effects of friction like heat generation and part wear/tear, both of which have negative implications to operations.

Air bearings offer an alternative by removing friction through a thin, but stiff, film of air to provide noncontact support. However, not all air bearings are created the same. The method of air distribution is a differentiating feature, one which must be considered when faced with stringent requirements like those seen now by the medical industry.

New Way utilizes a Porous Media™ design, leveraging the natural permeability of porous carbon to deliver an even distribution of air through millions of sub-micron sized holes. Our Porous Media Technology™ is inherent to every New Way product, enabling five key benefits for the medical industry.

Superior Precision

Superior Precision

With zero friction and surface averaging available through porous media, New Way products deliver nano levels of precision.- Improved Reliability

Uniform air distribution is critical to repeatability and overall product reliability. In orifice-based air bearings designs, pressure gradients develop creating instability. Not only can damaging crashes occur in this scenario, but products end up with inconsistent precision and performance. - Reduced Maintenance

The use of air removes the cost and time associated with component wear/tear and periodic maintenance associated with traditional bearing systems. - High-Speed Operations

With friction removed, operations utilizing porous media air bearings operate at higher speeds, without fear of damaging crashes. - Clean-Room Compliance

New Way products have been demonstrated to easily meet ISO 14644-1 Class 3 cleanliness. Additionally, the porous carbon acts as a sub-micron filter providing firm reasoning for their use in cleanrooms as stringent as Class 1.

With this broad spectrum of benefits, air bearings are attractive for use across an extensive range of applications. Let’s take a look at five examples where air bearings are transforming the medical industry.

Five Applications of Air Bearings: Transforming the Future of the Medical Industry

1. CT Imaging

CT scans are in high demand today for testing and diagnosis for a variety of diseases, including how the coronavirus impacts the lungs. Air bearings are no stranger to CT scanners. New Way’s radial bearings provide high-speed frictionless radial motion without noise or wear/tear, improving the efficiency of operations.

With the increased demand for access as well as enhanced precision, manufacturers are also using air bearings as an enabling technology for next-generation imagers.

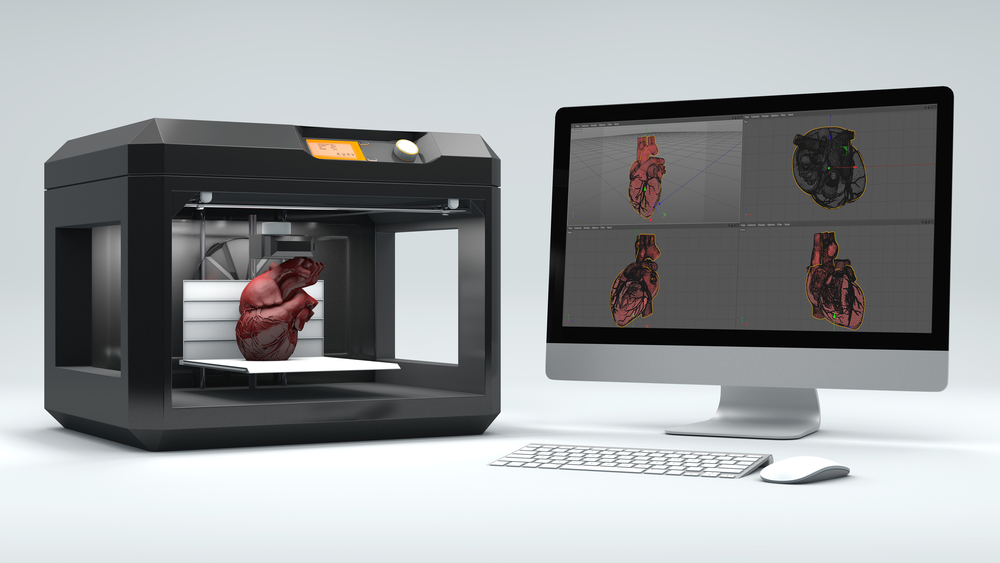

2. 3D Printing

As 3D printing becomes more prominent in the medical industry, manufacturers need to consider long-term production options to deliver both precision and operational efficiency. With proven success in high-precision printing, air bearings are a viable solution to accommodate the unique requirements for 3D printing of medical components and devices, such as:

- Orthopedic components

- Tissues/ligaments

- Organs

- Limbs

New Way products like Flat Round Air Bearings and Linear Slides are popular choices for the precision linear motion needed for 3D printing. With a standard product line available, New Way makes the large-scale manufacturing of these medical components more feasible.

3. X-Ray Inspection

With no room for even the slightest error, manufacturers rely on X-ray technology for inspection of everything from implantable devices to surgical equipment.

New Way offers Servo-Driven Rotary Stages as a solution for inspection systems. This precision rotary stage integrates the New Way Air Spindle with a slotless, brushless motor and standard/high-resolution encoder creating a design unmatched in precision and robustness.

With the increase in type and number of devices requiring inspection, air bearings offer a unique coupling of accuracy, high-speed operations, and repeatability ideal for the X-ray inspection market.

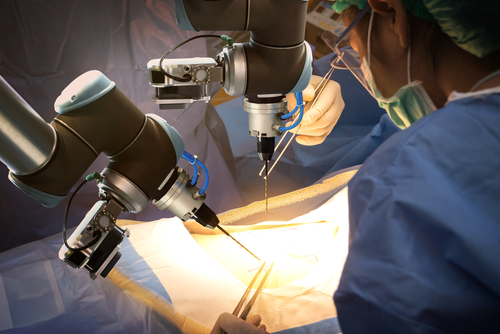

4. Robotic Procedures

The stakes are high for precision in robotic procedures—from the actual robot movement to the tools they use. The use of air bearings in the robot ensures confidence in precision, while also removing burdensome maintenance when compared to traditional bearing systems.

Medical tools require precision machining, a place where air bearings have a long history offering products for both linear and rotary motion options. Critical to the manufacturing of these products is a robust test system requiring an even greater magnitude of precision. New Way products have a proven track record of removing friction from the equation to get a true measurement of the product.

5. Medical Wearables

Medical wearables containing biosensors offer medical providers with important information for monitoring and screening of patients. These wearables use flexible materials with unique requirements for both precision and handling.

New Way Air Turns offer web handling for flexible materials. Air turns use the uniform air pressure to ‘turn’ or move the web through a system without making contact or wrinkles. Adjusting the air pressure allows for web tension and fly height control. With standard product sizes available, long-term and mass production of medical wearables becomes feasible with air turns.

Are You Positioned for the Future?

As the medical industry continues to evolve, air bearings provide an answer to meet stringent precision and operational requirements. New Way is ready with a large standard product line as well as custom solutions, delivering the benefits of Frictionless Motion®️. Our trademark method of removing friction through Porous Media Technology is in every product, assuring customers of repeatable performance and results.

Contact us today to take your medical application to the next level!