As we kicked off 2020, we sat down with members of the New Way® leadership team to talk about this year’s initiatives. Nick Hackett, President, Tim Claffey, Vice President of Sales, and Rich Hesse, Technical Sales Manager offered unique insight on New Way’s 2019 highlights and how that translates into where New Way is headed in 2020. The team identified five industries that continue to demand frictionless solutions, where only air bearings offer a viable solution. Let’s take a look at these industries and how New Way is prepared with solutions.

Five Industries to Watch for New Way Air Bearings in 2020

1. Automotive

Autonomous driving and self-parking initiatives are accompanied by increased demands on testing and inspection equipment. To accurately simulate environments free of human interaction, basic functions like steering and braking are seeing an increase in precision requirements. Part inspection is also experiencing tighter tolerances.

We are seeing increased use of New Way products such as flat round air bearings, spherical bearings, and air spindles as manufacturers seek to eliminate errors from friction to get a true read on performance. In 2019, New Way launched the Servo-Driven Rotary Stages product line useful in inspection and precision machining applications. In this one-stop product, an air spindle is fully integrated with a motor/drive assembly and an option of standard or high-resolution encoders. Servo-Driven Rotary stages are ideal for use in inspecting automotive parts such as cylinder bores and crankshafts.

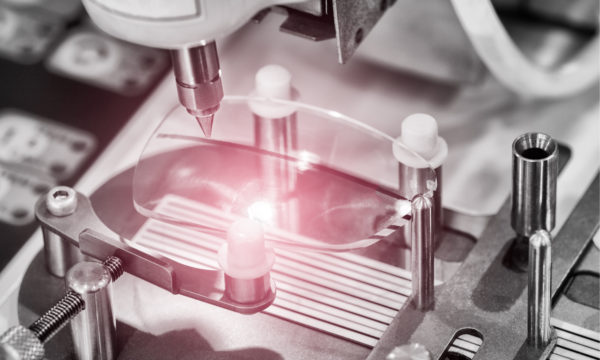

2. Optics

The optics industry persists in the demand for the precision of Fast Tool Servo applications. New Way’s Linear Slides are becoming a popular choice to meet this need. New Way’s Porous Media Technology™ ensures an even distribution of air across the bearing face while using vacuum replication to position the stage. This unique method of integrating the rail and bearing is delivering superior precision, straightness, and stiffness when compared to traditional ball-based systems. In 2019, one customer reported their best year in sales for New Way end-supported slides. From our participation at events like Optifab, we expect this trend to continue. Stay tuned in 2020 for updates to our Linear Slides, further improving our customer’s experience!

3. Turbomachinery

Recognizing the turbomachine industry’s challenge with maintenance, New Way offers New-Seal® as an alternative to traditional seals. Founded on our air bearings technology, New-Seal uses an Externally Pressurized Porous Media gas-bearing design to provide non-contact sealing for gases as well as liquids, fine powders, and slurries. In 2019, New-Seal introduced a standard line of double-faced seals. Behind the scenes in 2019 was more research & development with the expectation to introduce some new, exciting products for customers with rotodynamic machine applications. Stay tuned in 2020 for an announcement!

4. Flat Panel Display

“The flat panel display market continues to be our largest customer base, with expectations of more growth in 2020,” comments Claffey. In 2019, New Way expanded its Air Bar line to include the Positive Air (PA) Rails and the H-series Air Bar. Claffey and team have seen the stringent precision requirements for both handling and inspection, with the continued demand for displays, including flexible displays. New Way’s four styles of Air Bars offer this market a range of options from basic floatation to varying levels of vacuum pressure ideal for automated optical inspection. The ability to integrate air bar styles allows customers to create an end-to-end system specific to their needs.

5. Web Handling

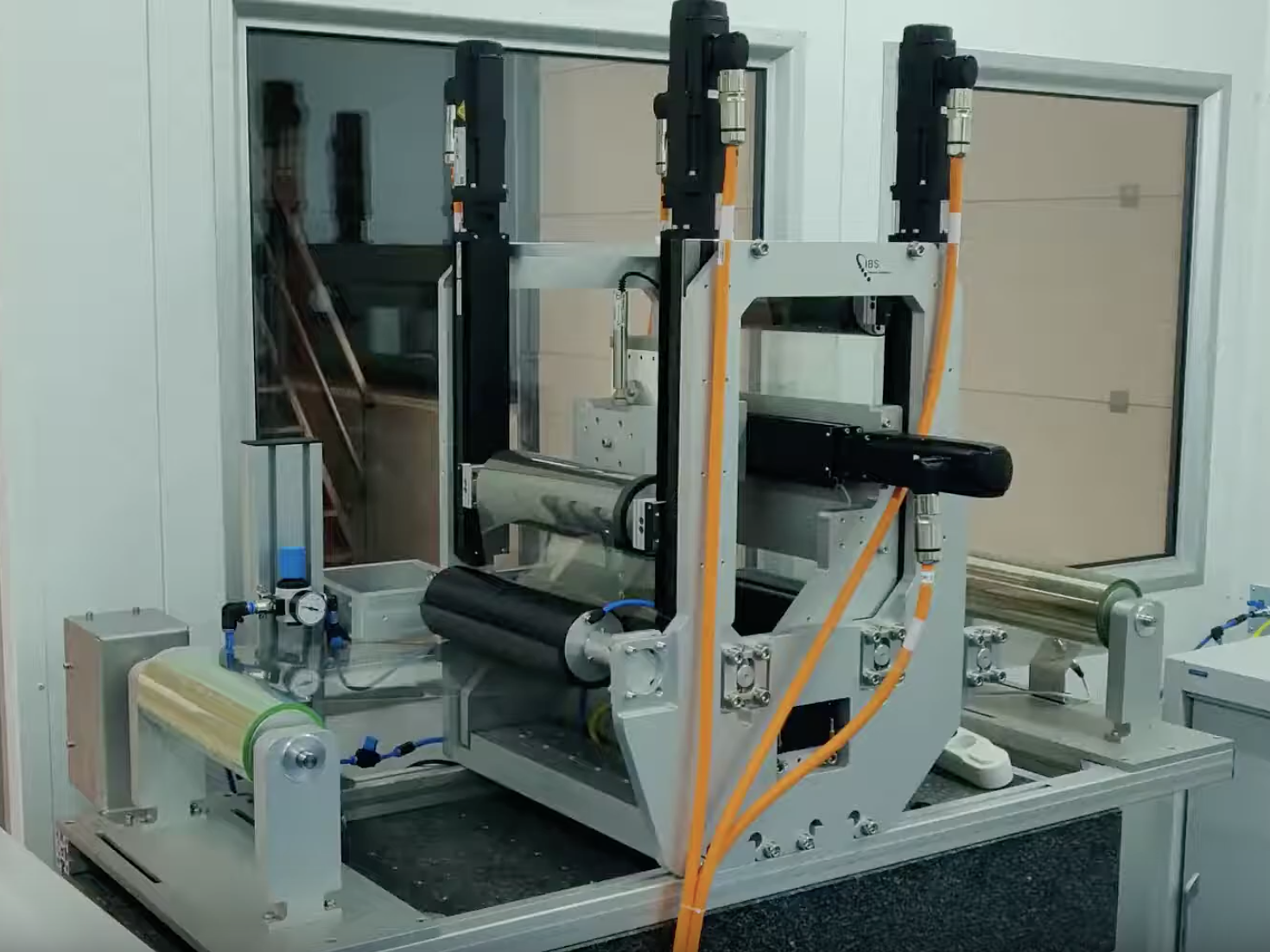

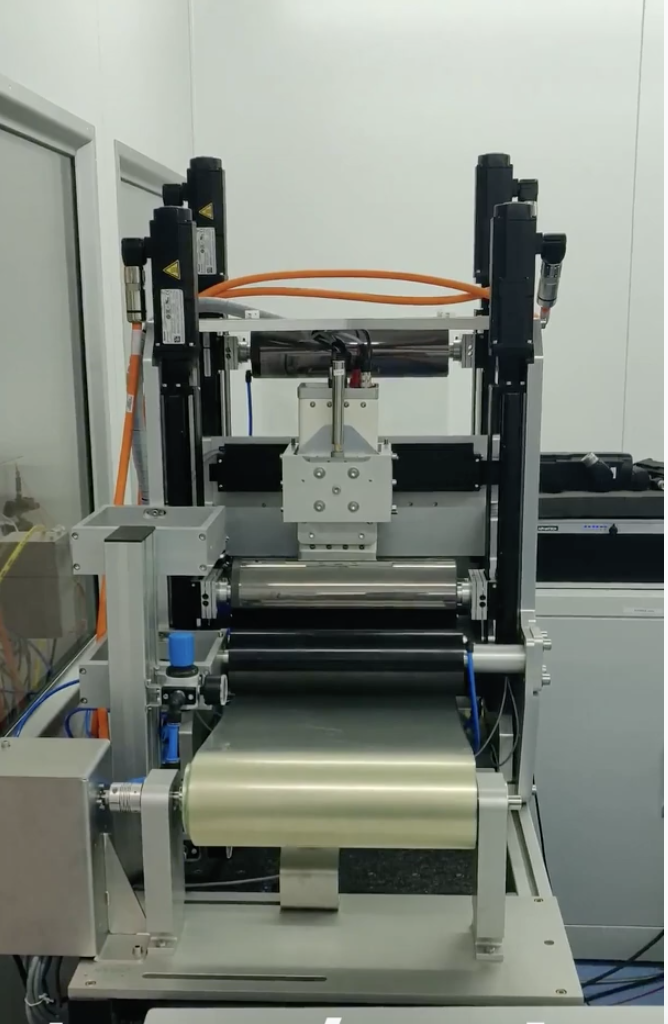

Floating and flexible materials are becoming more the norm, driving unique requirements on web handling systems. New Way Air Turns offer a non-contact solution to turn/convey flexible substrates. By wrapping porous media around a tube, the even air distribution enables the material to be moved up to 180 degrees without making contact. Air turn technology has been offered by New Way for several years, but previously only as a custom solution. In 2019, a standard product line of air turns was introduced to meet the growing demand in flexible web handling.

“New Way has been able to identify the market needs and create a standard line of Air Turns, minimizing cost and production time for our customers,” remarks Hesse. Companies like IBS Precision Engineering are already experiencing success with air turns in a laser inspection system, which they recently demoed at The Precision Fair in Veldhoven, Netherlands.

Continued Community Partnership in 2020

2020 wouldn’t be complete without New Way’s continued commitment to the community. With strong personal roots in the region, New Way believes strongly in building into students, the future of the community, through several initiatives. One initiative is to educate students and foster their interest in manufacturing opportunities through New Way’s continued participation in the What’s So Cool About Manufacturing contest. New Way also has plans to advance a grassroots campaign to offer employment opportunities for high school-educated students with autism.

“These students are often overlooked, but are gifted with an attention to detail ideal for the manufacturing environment,” remarks Hackett. Hackett is working with the Delaware Industrial Resource Center to bring awareness of non-traditional hiring to local manufacturing businesses.

Dedication to the community also extends to the precision engineering world. Tim Claffey, VP of Sales, has been selected to serve on the American Society of Precision Engineers (ASPE) nominating committee. Congrats to Claffey on this prestigious role! Claffey carries on New Way’s support of the ASPE; New Way’s CEO and Founder, Drew Devitt formerly served as an ASPE President.

Join Us in 2020!

It’s exciting to see the obstacles our customers have overcome with the use of New Way Air Bearings. New Way’s Porous Media Technology is opening the doors to new and improved technologies across a wide range of industries. Find out more in our free e-book, Five Industries Using Air Bearings to Deliver Disruptive Innovation.

Let us help you discover where Frictionless Motion®️ can take you in 2020! Contact us today to get started!