Air Bearing Facts

You’ve decided to go with New Way® and our frictionless technology to enhance your manufacturing process, but you have some more specific questions about our air bearings. Let’s go over some of the more common questions we field to learn how our air bearings work.

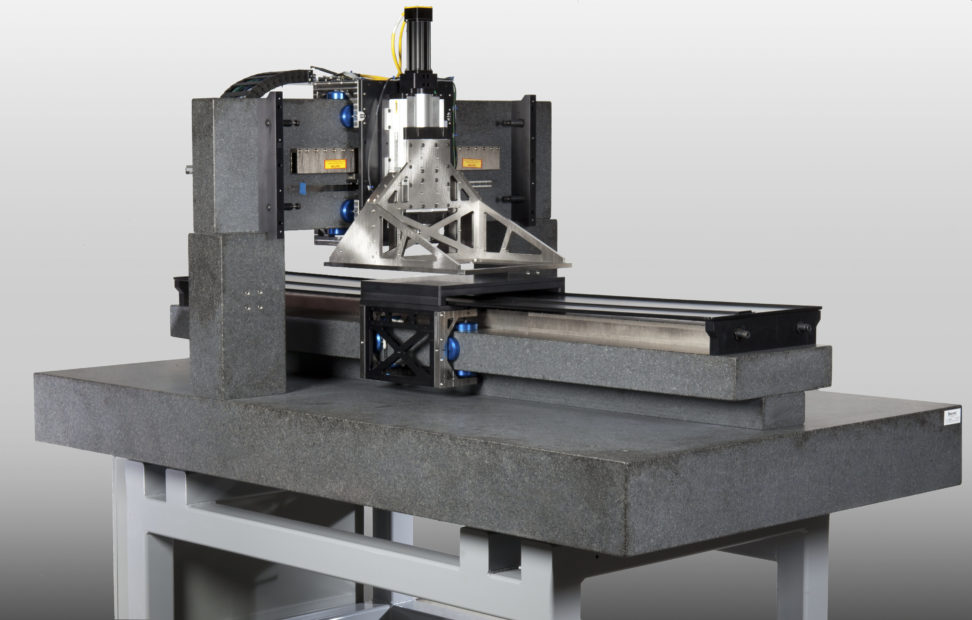

New Way’s air bearings can be easily integrated into your current manufacturing process and have been used in a variety of applications from semiconductor fabrication to vehicle testing to the aerospace industry. Despite the versatility of air bearings we field many common questions from our customers trying to figure out what our bearings are capable of and how they work.

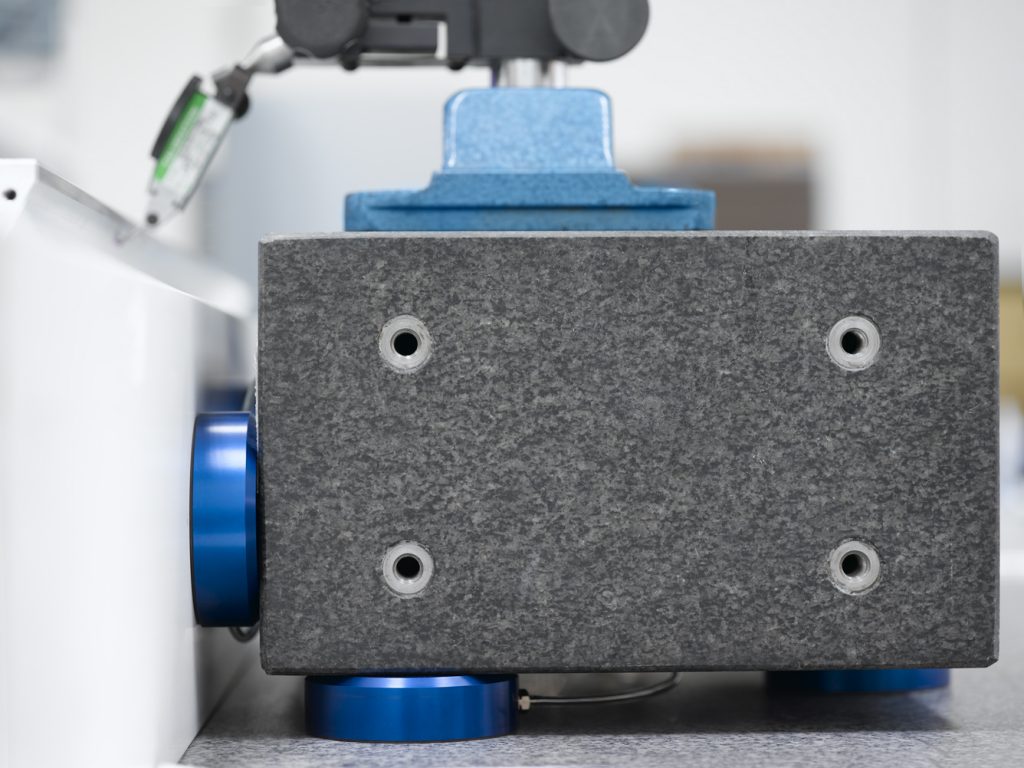

You only need to navigate a few pages of our website to learn that instead of passing air through machined grooves, our air bearings use a naturally porous carbon substrate. Air is forced through the millions of submicron passageways inherent in the material which creates a uniform and stiff air cushion at the surface of the bearing. If you look at our bearings they are not entirely made of this material. We house or attach the carbon to anodized aluminum and use epoxy to hold our porous media in place.

Soft But Crash Resistant

The soft carbon that underpins our Porous Media Technology™ maintains air gap stiffness in the face of scratches and cracks. But if air pressure through the material gets cut off for some reason, a crash could occur. In order to prevent possible damage by a “touch down” event, we recommend having low-pressure alarms installed to alert you when the air flow is reduced to undesirable levels. We also suggest installing a reserve air supply receiver.

This receiver can be triggered once the air supply reaches a specific value. Our bearings use so little air that having a reserve tank of about 4 liters of air will buy you enough time to shut down the machinery before a crash occurs. It’s always a good idea to test your system to make sure you have the proper amount of reserve air.

Although the substrate is soft it is still load bearing. We also finish our bearings to such high accuracy that they are much smoother than the ways or shafts they run on in typical applications. So even if the surfaces do end up touching, the damage is minimal as long as contact is on the order of a few minutes. This isn’t true for traditional bearings or orifice air bearings.

Bearings Work on Many Surfaces

It’s true that air bearings work best on extremely smooth surfaces. The load-bearing capabilities of our air bearings are guaranteed on finished surfaces with a mean roughness value of 16μm. Lapped surfaces are typically in the 2-8μm range while typical grinding operations produce a finish between 8-63μm. Most of the processes used to manufacture parts produce products with surface finishes that are well below the 16μm requirement.

It’s true that air bearings work best on extremely smooth surfaces. The load-bearing capabilities of our air bearings are guaranteed on finished surfaces with a mean roughness value of 16μm. Lapped surfaces are typically in the 2-8μm range while typical grinding operations produce a finish between 8-63μm. Most of the processes used to manufacture parts produce products with surface finishes that are well below the 16μm requirement.

Holes and grooves in a guide surface shouldn’t be a problem as long as the openings are not too large. Larger openings reduce the surface area where air pressure can build up which will cause the bearings to touchdown. The holes and grooves should be free of raised edges that the bearing can run into.

It may also surprise you that seams are a tricky consideration for air bearings. In order for the bearings to fly over a seam properly, the difference in height in either side of the seam needs to be less than 25% of the width of the air gap. For example, if your air gap is 10 microns, the height difference on either side of the seam has to be 2.5 microns or less. While this is achievable, it would take some work. So it’s best to avoid this situation if possible.

Taking Care of Your Bearings

Unlike traditional bearings that require lubricants because they make contact with surfaces while moving, our porous media air bearings do not require regular maintenance because there is no contact!

Orifice air bearings are susceptible to clogs by dirt and other particulates. Since our bearings are made from porous graphite, they act as a natural filter to remove any particulates or dirt that can contaminate the air supply. If any dirt or residue somehow gets on the bearings or guide surfaces, you simply wipe it clean with isopropyl alcohol while also applying air pressure.

If you have questions about specific New Way products, check out our FAQs section for more answers to all your pressing air bearing questions. You can also contact us today to learn more about our products.