How to Take the Anatomy of an Air Bearing and Make It Work for You

Porous media air bearings provide proven advantages where precision motion or positioning is required. From coordinate measuring machines and precision machine tools to high-speed, precision positioning applications, air bearings are an outstanding solution. With optimal functioning in a multitude of surroundings, such as clean-room environments and sandblasted ceramic manufacturing settings, air bearings are a natural choice.

The Anatomy of an Air Bearing

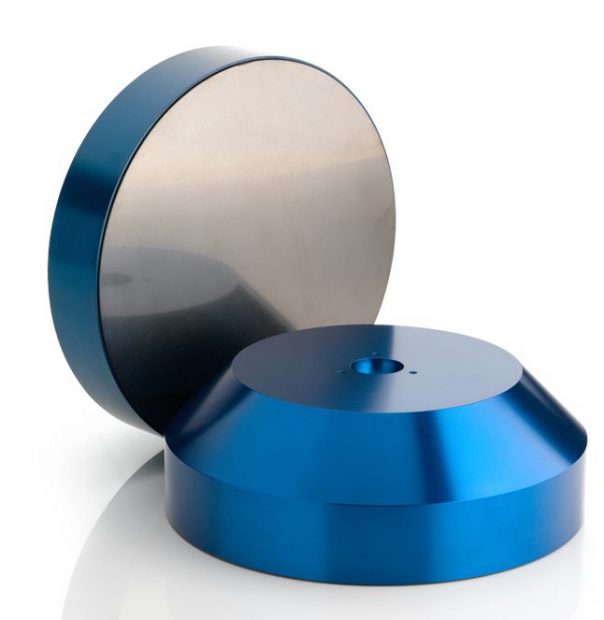

New Way offers products in many shapes and sizes, including custom configurations, but the standard-bearer for the company’s porous media product line is the Flat Round Air Bearing.

Available in 11 standard sizes, from 25mm to 300mm in diameter, it provides a representative air bearing profile.

The Flat Round Air Bearing integrates the company’s proprietary porous media technology with a (New Way Blue) anodized aluminum housing in ‘puck’ form. The lapped bearing face, featuring a surface flatness to 1 micron, actually consists of millions of sub-micron-sized holes, delivering an even air-pressure distribution.

Key Considerations

Clean Dry Air (CDA) is important for optimum air bearing performance, but the bearings are incredibly robust and remain functional even with less than ideal air supply. Typically, New Way products use compressed air at 60psi, but different applications often call for different air pressures.

The air supply is delivered through a clear, polyurethane tube which attaches to the side of your bearing using a barbed brass fitting. Tubes and fittings come in sizes and configurations to meet your specific needs.

Two different types of ball mounting screws are available for applying your air bearings: New

Way’s Round End Ball Mounting Screws, which are applied with a retaining clip for applications with frequent repositioning requirements, or Flat End Ball Mounting Screws, which are designed to enable height adjustment from either end.

The simplest mounting method of all uses one of our stainless steel balls, which act as a self-leveling interface between the air bearing and your application.

Air bearings are usually run on granite or hard-coat aluminum surfaces, but they can also

operate on steel (as long as there is no oil, rust or corrosion on the surface), ceramics or specialized glass (as long as the glass features a zero coefficient-of-thermal expansion).

The surface finish of your guideway should be 16 RMS or better, ground or lapped. Local flatness-straightness (the area under a bearing at any given time) should be flat to within 50% of the air gap.

Air Bearing Applications

The anatomy of an air bearing enables a broad range of benefits including zero friction, zero wear, high speed, high acceleration, straighter motion, as well as smooth and silent operation. Further, air bearings do not require lubrication, eliminating problems associated with oil.

This makes air bearings ideal for an array of linear and rotary motion applications in industries as diverse as aerospace and automotive, audio and optics, medical and metrology, and much more. Air bearing capabilities also enable non-contact handling of substrates in flat or roll-to-roll

manufacturing; even the sealing and balancing required in oil and gas turbomachinery.

How to Take the Anatomy of an Air Bearing and Make It Work for You

The anatomy of an air bearing makes it robust; flexible enough to accommodate applications in the cleanest or the dirtiest of environments.

When you’re ready to design air bearings into your application, you’ll find specifications for each of New Way’s standard air bearing products online, including an engineering drawing (sample) complete with the components described in this post. For more in-depth information about the design, application, care, and maintenance of New Way products, download the New Way Application and Design Guide.

Ready to apply the proven advantages of porous media air bearings to your application? Download our ‘What Porous Media Air Bearings Can Do For You’ Infographic. This simple tool provides a clear, concise rationale for air bearing consideration where precision motion or positioning is required. Or, contact us directly today for your complimentary consultation!