As manufacturing processes produce next generations of substrates, conveyance systems with traditional roller bearings no longer can achieve high levels of yield and throughput.

For example, new classes of glass sizes pose new challenges in the conveying process associated with processing accuracy, control, and output. As a result, manufacturers need new solutions to optimize their processes.

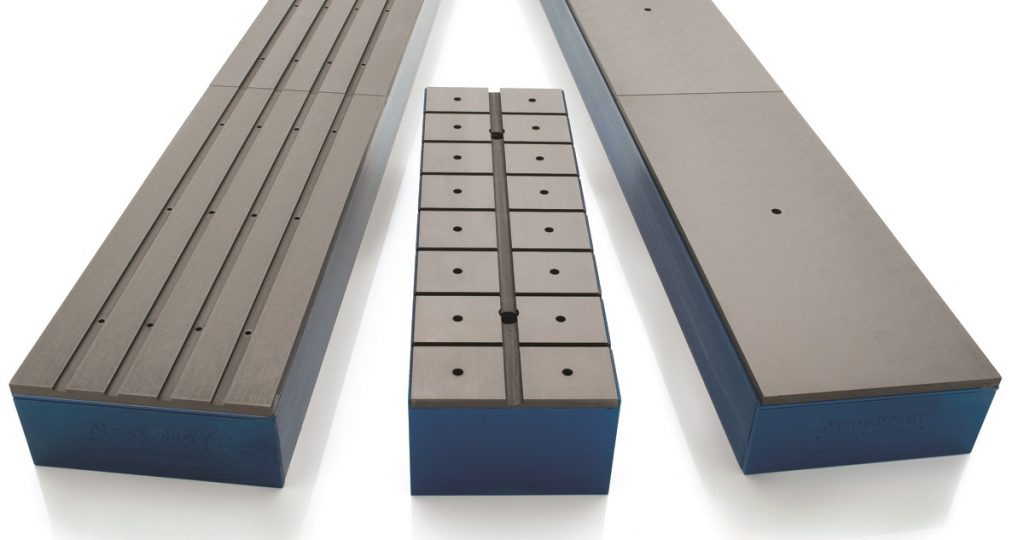

New Way® revolutionizes conveyor bearing technology with its new line of patented air bars that provide non-contacting conveyance and sub-micron level control of substrates during manufacturing for greater outcomes.

What Are Air Bearings?

Using a combination of air pressure and vacuum, the air bars support thin workpieces, particularly glass, for more precise inspection, coating, cleaning, patterning, and other processes. Operating on the principles of New Way’s proprietary Porous Media Technology™, the air bars float on a thin film of air distributed through millions of sub-micron sized holes across its carbon bearing surface. Simultaneously, a set of vacuum holes and grooves use atmospheric force that pushes and flattens glass against the air film in a safe non-contacting precision zone to reduce thickness errors and achieve higher control.

Using vacuum in conjunction with air pressure, the air bars provide a higher level of processing accuracy unachievable with traditional conveyor roller bearings. With a 10- to 120-micron substrate fly height range and 5-micron height control, the New Way Air Bars offer:

Greater control process accuracy, and yield in conveyance systems over conventional contact bearings or orifice-based air bearings.

Greater control process accuracy, and yield in conveyance systems over conventional contact bearings or orifice-based air bearings.- Noncontacting operation that eliminates surface friction and problems with wear and surface damage.

- Reduced external clean dry air consumption and virtually no disruptive air flow sources associated with extruded products using simple orifices or plate-and-nozzle systems.

- A carbon surface that never particulates during operation to avoid contaminating a cleanroom environment.

Two Models of Air Bars Address Different Application Requirements

New Way offers its air bars in two configurations:

Transition Air Bars

Deliver controlled, non-contact glass handling capability for conveying, processing, and inspection applications. Engineered to reduce system and operational costs, these modular components operate at high-speeds with low air flow. When using a vacuum, they sustain vertical glass stability with a flying height range of 20 to 120 microns. Transition Air Bars are available in four lengths (500 mm to 1250 mm) to build arrays required for the largest glass generations.

Precision Air Bars

Assembled in arrays near or under precision glass inspection and optimized process stations for Flat Panel Display (FPD) or Photovoltaic (PV) manufacturing. These modular, positioning components provide greater precision, stiffness, and damping than traditional air bars and greater control (to ±5µm) than orifice-based air bars.

Assembled in arrays near or under precision glass inspection and optimized process stations for Flat Panel Display (FPD) or Photovoltaic (PV) manufacturing. These modular, positioning components provide greater precision, stiffness, and damping than traditional air bars and greater control (to ±5µm) than orifice-based air bars.

Find out more about the advantages of using New Way Air Bars in different conveying applications or go right to the product page to find out more about the operating specs of different air bars.

You can also request information through our web page. https://www.newwayairbearings.com/support/contact-information/request-information/