Three Unique Benefits of New Way’s Spherical Air Bearings

Spherical air bearings from New Way provide significant advantages in comparison to traditional spherical bearings. Our frictionless air bearings use proprietary Porous Media Technology™ to provide an air cushion that carries the load without contact to the moving parts. This design delivers low coefficients of friction, low maintenance, no need for lubrication, and high precision in a variety of industrial applications. The proper air gap is maintained and is key to providing the precision and accuracy needed for numerous applications.

A Brief Look at the History of Spherical Bearings

So how has technology evolved and how does New Way deliver superior performance? Traditional friction type self-aligning spherical bearings were first used by James Nasmyth around 1840 to support line shaft bearings in mills and machine shops. Although spherical bearings have evolved from the original design, their functionality remains the same: they permit angular rotation about a central point in two orthogonal directions, within a specified angular limit based on the bearing geometry. Typically roller type bearings using friction are used to support a rotating shaft in the bore of the inner ring that must move not only rotationally, but also at an angle.

The current design of spherical bearings has different roller bearing arrangements, such as single row barrel bearings, single row thrust bearings or double row convex bearings. All rely on roller bearing friction to achieve the load and functional movements. However, the concerns of friction bearings are the limitations of speed, lubrication, and maintenance requirements and excessive wear.

Three Unique Benefits of New Way’s Spherical Air Bearings

New Way’s offerings of frictionless spherical air bearings not only support a sphere, but their Frictionless Motion®️ design makes them unique from traditional spherical bearings and provides the benefits of improved performance. New Way’s air bearings can provide:

New Way’s offerings of frictionless spherical air bearings not only support a sphere, but their Frictionless Motion®️ design makes them unique from traditional spherical bearings and provides the benefits of improved performance. New Way’s air bearings can provide:

- Reduced maintenance and wear

- High Precision and repeatability

- Customized design for special applications

New Way Offers Frictionless Spherical Air Bearings

New Way manufactures a standard line of designed-to-order spherical air bearings that fit a variety of applications. The housings are stocked and we await your radial specifications and resolution requirements. The S36 Spherical Air Bearing Series offers a wide range of sizes, from 25mm to 200mm, accommodating an even broader array of sphere sizes to fit any application. For example, a 65mm spherical air bearing can be manufactured with a radius from 65mm up to 325mm.

New Way also manufactures custom spherical air bearings to your specifications. Custom-shaped housings are engineered as determined by your application, in sizes larger than are available in our standard product line.

Applications for Spherical Air Bearings

So how can New Way’s spherical air bearings with the benefits of Frictionless Motion®️ be applied for industrial applications? Here are some areas of potential uses:

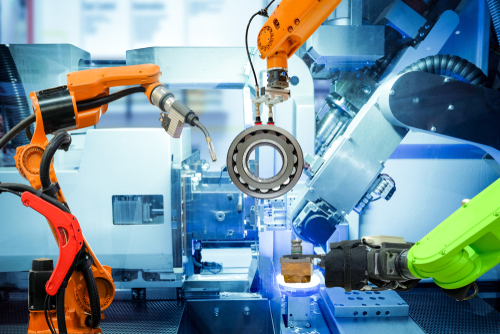

- Robotics with Frictionless Motion®️ for prolonged life

- Industrial applications with needs of precision motion and repeatability

- Applications for high tech aircraft maneuverability

- Machine and tool manufacturing with Precision Cutting

New Way manufactures custom spherical air bearings for use in a wide range of industrial applications. These bearings support a sphere on a thin layer of air, providing the benefits of Frictionless Motion®️. Learn more about spherical air bearings.

Contact us for a free consultation regarding frictionless spherical air bearings for improved performance.