The AFRL wanted to develop a sub-micron system which can simultaneously apply tension and compression to a sample for real time diffraction microscopy imaging. Thus began development on the Rotational and Axial Motion Systems (RAMS) apparatus from PulseRay, and the beginning of Basil’s long working relationship with New Way Air Bearings.

New Way Air Bearings® has seen OEMs integrate our bearings into all manner of precision applications, but perhaps none as precise as Pulseray. Headquartered in Ithaca, New York, PulseRay Inc is the brainchild of CEO and chief engineer Basil Eric Blank. 10 years ago Basil was contacted by the Metals Branch of the Materials and Manufacturing Directorate within the Air Force Research Laboratory (AFRL) with an ambitious goal.

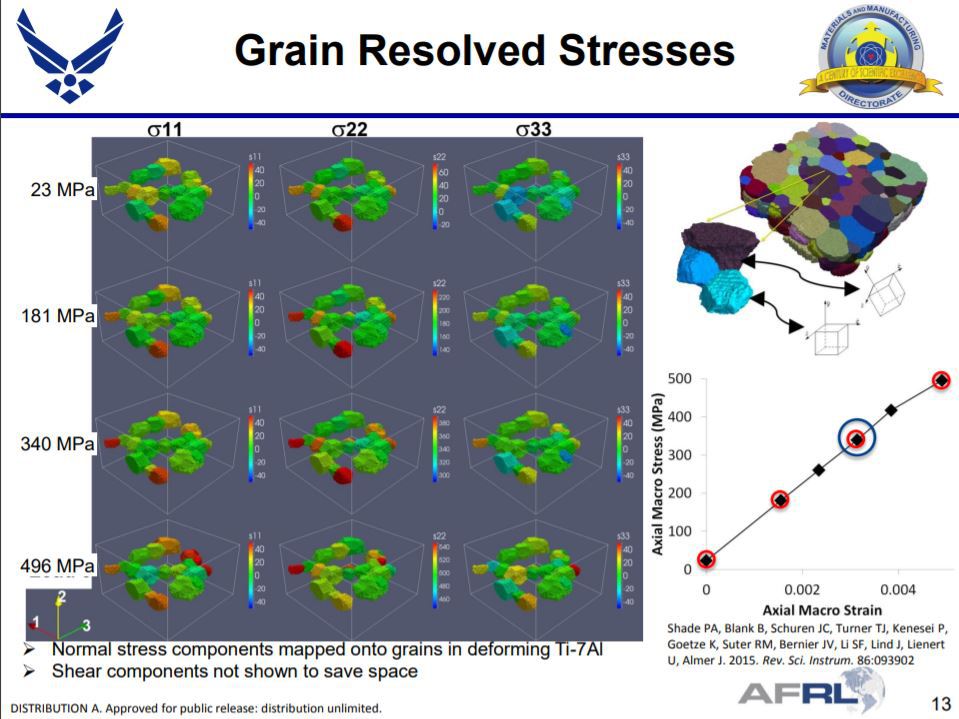

The AFRL wanted to develop a sub-micron system which can simultaneously apply tension and compression to a sample for real time diffraction microscopy imaging. Thus began development on the Rotational and Axial Motion Systems (RAMS) apparatus from PulseRay, and the beginning of Basil’s long working relationship with New Way Air Bearings.

Finding Superior Performance and Support with New Way

When Pulse/ray began development on RAMS I, Basil already recognized the limitations of conventional bearings, and built the system using a competitor’s air bearing system. “Right out of the box it didn’t work”, Basil recalls. This initial failure soured his view of orifice bearings even before they could perform characterization tests of the system.

When Pulse/ray began development on RAMS I, Basil already recognized the limitations of conventional bearings, and built the system using a competitor’s air bearing system. “Right out of the box it didn’t work”, Basil recalls. This initial failure soured his view of orifice bearings even before they could perform characterization tests of the system.

This experience sent Basil looking for a higher quality component, and eventually to New Way Air Bearings. When asked whether he had any concerns he responded with a laugh. After his first experience with air bearings, “everything was a concern!” Nevertheless, working with New Way was an “awesome experience” from the get go, he added.

“Rich Hesse is great to work with. It’s just great to work with a supplier who can provide the technical information you need, and can really give you guidance on how best to use their product”, said Basil, speaking of his experience when consulting with New Way on the requirements for his bearings. He stressed that having dimensional information and expertise regarding how to interface air bearings with existing systems and complete load curves was invaluable towards the integration process at Pulseray.

Going Above and Beyond for Precision Motion

The first RAMS system was a test bed in every way—not just to assess the validity of the system itself, but also the positioning accuracy which could be expected from an independently mobile system positioned within an existing HEDM frame. At the time, AFRl’s ideal goal for this system was single-micron position precision in rotation of the sample. Prior systems were not repeatable, and produced different grain boundary patterns with each test, and so necessitated a more precise solution.

Once RAMS I was up and running, Basil discovered his system was capable of far below the desired one micron precision. RAMS I was ultimately found to produce 250 nm precision in both rotation and axial motion, shocking the program office who had not even set a goal for axial precision. This degree of fidelity arose as a natural function of the Porous Media™ bearings’ frictionless, inertia free motion, leading to a new patent for the system, and an award for the team which funded Basil’s work.

A Game-Changing Partnership

RAMS I was only the beginning. Now Pulseray is working on RAMS IV, which offers the ability to apply sinusoidal torsion and XY translation for beam alignment. Since the development of RAMS I, Pulseray’s systems and their Porous Media foundation have been used by Pratt & Whitney, Rolls Royce, and General Electric to inspect for crack propagation in aerospace-grade alloys. To date, the RAMS system has been used in over 30 experiments by private partners, top research universities and national laboratories, with further funding allocated for the next generation of RAMS systems.

“I wouldn’t send them anywhere else”, said Basil, reflecting on his experience with New Way Air Bearings, which has now grown into a mature, decade-long professional partnership. The RAMS system now utilizes custom-made bearings from New Way both within the frame and in the driving motor.

Contact Us

The services provided to Pulseray are available to all of our customers for any application. Our design team is standing by to develop air bearings custom made for your purpose. With our extensive background in retrofit bearings, we can produce motion solutions for clean sheet designs or existing setups.

To learn more, download our free ebook “Air Bearings for Additive Manufacturing” to discover how New Way offers revolutionary solutions to manufacturing industries. For any additional questions, contact us anytime!

Learn More About the Porous Media Difference