New Way Air Bearings provided Flat Round Air Bearings to the European Synchrotron Radiation Facility, enabling their groundbreaking ID32 RIXS Spectrometer.

Here at New Way Air Bearings ® , we’re proud to support the cutting edge in innovation across a wide array of industries, and today we want to talk about how our porous media bearings help to advance the very forefront of science. At the European Synchrotron Radiation Facility (ESRF), custom made flat round air bearings enabled the development of the first of its kind ID32 RIXS Spectrometer for the polarizing x-ray analysis of magnetic and electronic structures. Read on to learn more about this fascinating instrument, and how Frictionless Motion™ enables never before seen precision.

What Is The Instrument?

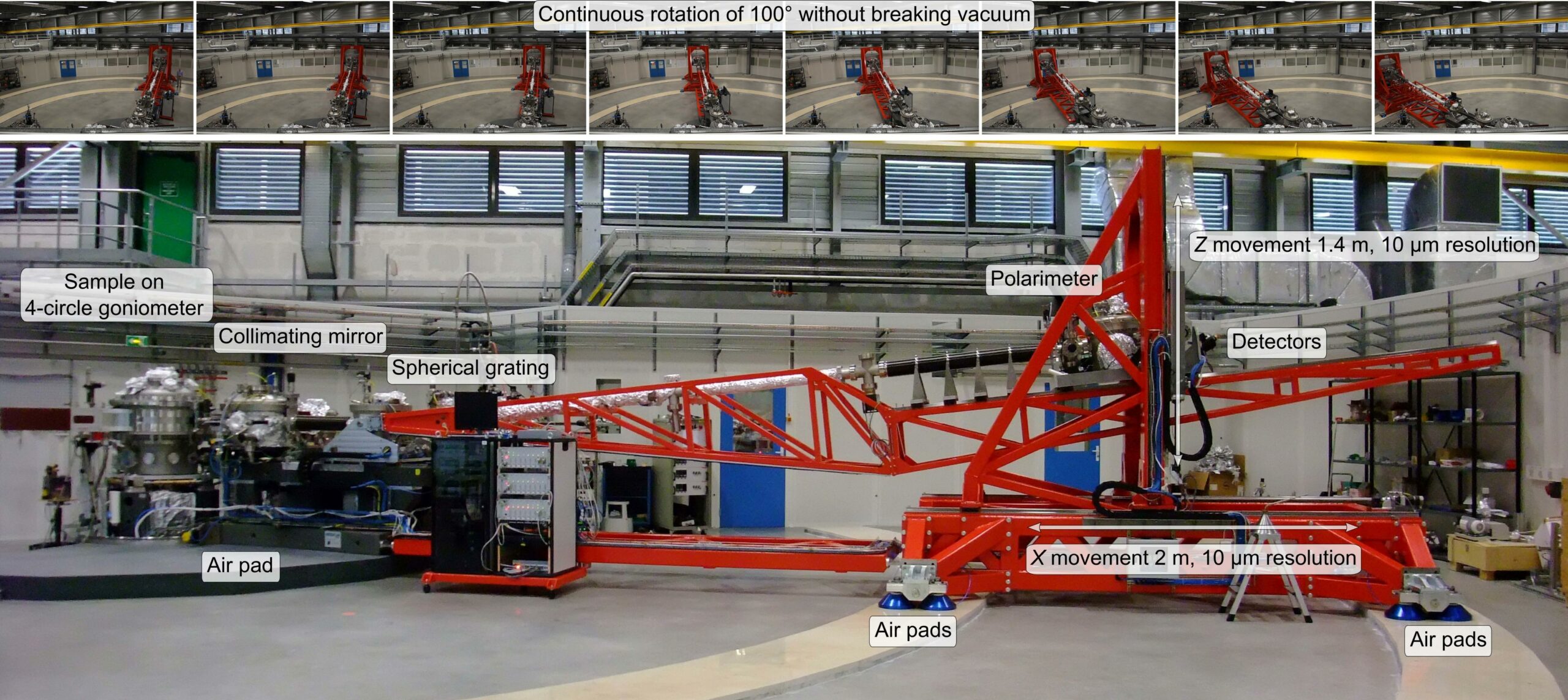

Per the ESRF, the ID32 Resonant Inelastic X-Ray Scattering (RIXS) spectrometer is the world’s leading instrument of its kind, allowing for 3D mapping of the energy and momentum dependencies of charge and collective excitations. This is primarily applicable to studying semiconductors and semimetals, resolving such aspects of their magnetic behavior like spin, orbit resolved magnetic moments, magnetic anisotropies, and more. The 6.3 ton RIXS instrument is capable of rotating 100° about the sample geometry on custom built air pads. The air pads easily support the weight of the detectors and polarimeters, while allowing for the nanoscale accuracy required for the ID32’s unparalleled resolution.

What Is An Air Bearing Pad?

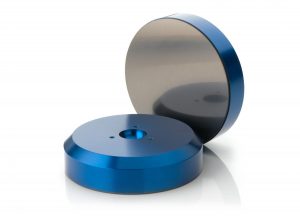

Air bearing pads are among our oldest products, and th e Flat Round Air Bearing is no exception, with decades of usage demonstrating its reliable, precise behavior. Whereas orifice bearings push air through a series of grooves or holes and are therefore susceptible to collapse, porous media bearings evenly distribute the thin air film across the entire bearing face through the micro perforated carbon surface. This produces a highly stable motion system which, thanks to its non contact operation, confers a number of unique benefits.

e Flat Round Air Bearing is no exception, with decades of usage demonstrating its reliable, precise behavior. Whereas orifice bearings push air through a series of grooves or holes and are therefore susceptible to collapse, porous media bearings evenly distribute the thin air film across the entire bearing face through the micro perforated carbon surface. This produces a highly stable motion system which, thanks to its non contact operation, confers a number of unique benefits.

Why Is An Air Bearing Pad Necessary?

Firstly, our air bearings are modular. A single 300mm Flat Round Air Bearing like the RIXS is mounted on can support in excess of 4,000 lb., and so a stage can be designed with as many as required in order to support the payload. While contact bearing solutions demand increasingly complex maintenance requirements and larger maintenance time as they grow larger, air bearings of all sizes operate in the same manner, and require the same, minimal maintenance regimes.

Secondly, precision is the ultimate consideration for an institute like ESRF. Our bearings are already deployed across the globe to meet such requirements in similar environments, like at the Keck Observatory, where custom built rotary stages enable 1.1 arcsecond position and target acquisition times of 15 minutes, down from over an hour. For the ID32’s 11m long scattering arm and its connection to the differentially pumped seal which enable complete vacuum during rotation, contact bearings are simply too risky. Their inherent inertial results in unwanted motion, while the eventual breakdown of lubricants and particulates leads to spalling and eventual lockup of the bearing unit. Any of these failure points could be catastrophic for an instrument like the ID32 Spectrometer, potentially breaking vacuum during a test, or causing mechanical damage to the system itself.

Custom Engineering On Request

The RIXS unit is mounted on sets of 300mm Flat Round Air Bearings, with custom mounting hardware to ensure both planarity and even weight distribution. We offer both a comprehensive lineup of off the shelf components and their appropriate mounting hardware ready for use, both we also offer custom engineering services, to ensure our bearings can fit into your system with ease. Retrofitting is a core component of our business, with decades of experience for clients such as Sheffield and Canon.

Contact Us

If you want to learn more about our work with ESRF and their ID32 Spectrometer, or you already have an application in mind you want to get started on, please contact us, and our dedicated engineering sales team will get back to you!

Learn More About the Porous Media Difference