New Way Air Bearings and IBS Precision Engineering collaborated on full carbon air bearings for SparkNano’s revolutionary spatial ALD technology

New Way Air Bearings ® has a longstanding relationship with IBS Precision Engineering, who incorporate our porous media air bearings into their products like the ISARA 400, the world’s most accurate 3D coordinate measuring machine. Our partnerships with integrators of our products is just as important as our relationship with OEM’s, like how IBS recently acted as an integrator of custom New Way bearings on behalf of Sparknano.

Who is Sparknano?

Sparknano acts as an OEM for spatial Atomic Layer Deposition (ALD) technology. Spatial ALD is critical to the green revolution, as it is used in the production of energy storage, generation and conversion technologies. For example, hydrogen electrolysis requires iridium and platinum as catalyst elements, and Sparknano’s ALD processes allow for significant reductions in the iridium required, on the order of 40x less. This massive cost savings helps make numerous technologies not only commercially viable, but profitable as well.

The Challenge of Spatial ALD

For their spatial ALD process, Sparknano’s engineers required an accurate, scalable and cost effective machine design with a mechanically stiff structure and as little Z axis motion as could be prescribed in the system. Their solution was to have the substrate move beneath the injector head, but this involved multiple stringent requirements. Aside from mechanical stiffness and Z axis fixturing, the environment must remain particulate and grease free, as well as handling temperatures in excess of 250 degrees C.

A Custom Made Solution

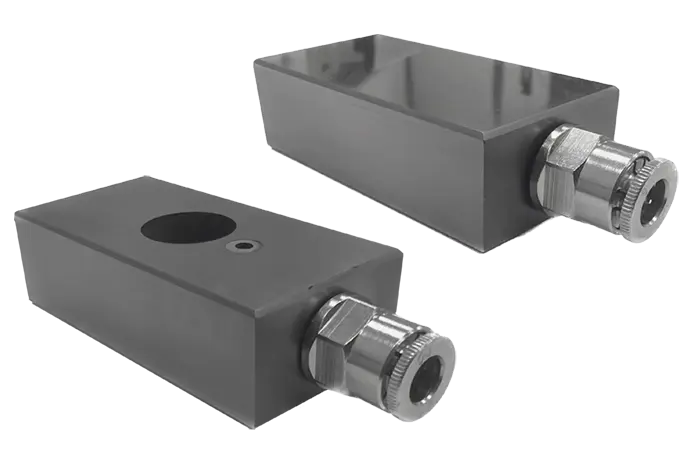

IBS came to us with Sparknano’s requirements, and our engineering team devised a brand new solution to meet their exacting needs. All of our air bearings are already ISO class 1 cleanroom compliant by virtue of their porous substrate, and exhibit highly stiff behavior ideal for machine platens. Additionally, porous media bearings have zero dynamic components, eliminating grease, lubricants or fluids of any kind. High heat environments were a new challenge for us, and one we tackled with enthusiasm. Traditionally, our Externally Pressurized Porous (EPP) Media © is mounted within anodized aluminum housings, however the high temperatures within Sparknano’s Labline system meant expansion and contraction, even by microscopic amounts, could jeopardy the process gap height during spatial ALD. By constructing flat rectangular air bearings entirely from our proprietary carbon, this monolithic design is high heat compatible and remains stable under intense thermal loadings. Once mounted on the substrate table, our bearings produce a consistent 5 micrometer gap.

Robust, Scalable Results

Sparknano was “delighted’ with their new porous media air bearing system, providing them a stable, lubricant and particulate free process with infinite lifetime performance and zero maintenance requirements. “From the design phase to the final product, we experienced a genuine partnership with UBS, which greatly aided SparkNano is the process of scaling up and industrializing our spatial ALD lab and fab equipment”, said Jeroen Smeltink, systems architect for SparkNano.

Beyond the success of this initial system, the work undertaken by New Way Air Bearings and IBS lays the groundwork for a new product line of spatial ALD equipment. Sparknano’s ultimate goal is to produce scalable solutions for commercializing ALD, and with our bearings’ modular capabilities, they can easily scale to support any required load capacity.

Contact Us For Custom Engineering

If your system or process is in need of precision that contact bearings simply can’t provide, please reach out to us! We’re happy to work with you or your existing system integrator to identify and develop a custom porous media bearing solution for you!

Learn More About the Porous Media Difference