Airpot® Corporation, an industry leader in force pneumatics, motion, and displacement, turned to New Way® when they wanted to test their latest product. While Airpot has a long history of providing linear actuation and motion damping across their product line, they too, like New Way, recognize the value of Frictionless Motion®️, which guided the development of their Airpel-AB Air Cylinders.

Airpot® Corporation, an industry leader in force pneumatics, motion, and displacement, turned to New Way® when they wanted to test their latest product. While Airpot has a long history of providing linear actuation and motion damping across their product line, they too, like New Way, recognize the value of Frictionless Motion®️, which guided the development of their Airpel-AB Air Cylinders.

Similar in operation to one of New Way’s own air bearings, and as explained by Tom Lee, the vice president of engineering at Airpot Corp, “The supplied pressure creates an air bearing between piston and cylinder, allowing for truly Frictionless Motion®️ of the piston.”

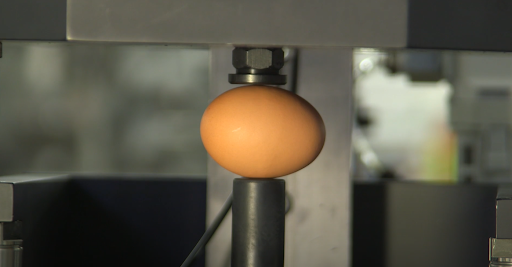

This makes the Airpel-AB ideal for counterbalancing vertically guided loads, with the system capable of balancing 50 pounds on top of an egg.

Airpot Proves Precision Pneumatics with Air Bearings

In order to prove the precision and pedigree of their latest product, Airpot required a test rig that could be positioned as precisely as the product it was testing. Naturally, Airpot sought out a system built on air bearings. New Way helped develop the counterbalancing application which Ken Lafluer is shown testing. This testing rig completely eliminated friction by supporting a 50-pound load on a New Way Linear Slide, which itself was actuated by a pair of 24mm bore Airpel-AB Cylinders.

In order to prove the precision and pedigree of their latest product, Airpot required a test rig that could be positioned as precisely as the product it was testing. Naturally, Airpot sought out a system built on air bearings. New Way helped develop the counterbalancing application which Ken Lafluer is shown testing. This testing rig completely eliminated friction by supporting a 50-pound load on a New Way Linear Slide, which itself was actuated by a pair of 24mm bore Airpel-AB Cylinders.

As Lafleur demonstrates, when air is introduced into the Airpel-AB Cylinder, the load rises smoothly, and then pressure is backed off until the load is counterbalanced. This is where the Frictionless Motion®️ of our air bearings compliments that of the Airpel Cylinder.

The Airpel-AB Cylinder could not be truly proven out with a slide system based on ball-bearing products. The inherent inertia and friction inside a contact bearing unit would allow it to resist minute loadings before the drop from static coefficient of friction to dynamic coefficient of friction was overcome. In the test rig we helped develop, our linear slide has a friction coefficient of zero, and so any loading, however small, is enough to move the unit from its perfectly counterbalanced state. It can sometimes be difficult to envision truly Frictionless Motion®️, but even the presence of a quarter is enough to cause the linear slide to drop, demonstrating how precisely even large stages can be positioned with a system built solely on air-bearing-based products.

Safety and Durability

An important consideration for any company is safety, and air-bearing-based products offer this in spades. Lee notes that even if a linear motor were to lose power, the Airpel-AB cylinder will continue supporting the load, and should the air compressor lose power, the linear slide would slowly depressurize, preserving the load and the guideway.

Products

Airpot offers their Airpel-AB Cylinder in four sizes, from 9.3mm bores up to 32.5mm, capable of actuating loads between 2g and 58kg.

New Way offers our Linear Slides in four configurations. Both end-mounted and continuously supported, the various linear slide configurations are capable of 1-meter travel and up to 600 pounds of supported load.

A Future Built on Air Bearings

New Way Air Bearings is proud to support Airpot in demonstrating what their technology is capable of, and we look forward to developing the next generation of frictionless technology with them.

If you’d like to learn more about air bearings and help separate fact from fiction, download the Air Bearing Mythbusters Infographic, and then contact us so we can discuss how air bearings can best meet your needs!

Learn More About the Porous Media Difference