Discover Three Benefits of Air Bearings for the Aerospace Industry

It’s no secret.

The aerospace industry has been in the spotlight the last several months as investigations continue into the failures of the Boeing 737 Max. The failures and resultant catastrophes have sparked debate around the FAA certification process, training, and safety, just to name a few. As findings are developed, it’s safe to say there will be changes recommended to standards and protocols in an effort to prevent similar tragedies in the future. No doubt the lessons learned from this disaster will extend beyond the development of aircraft, but to other products across the aerospace industry.

Investigations like these trigger lots of questions, including the quality and rigor of testing procedures. Designing and building advanced technologies such as aircraft, satellites, and rockets is a challenge unto itself, however, the testing of these products face their own set of unique challenges. As products go from component level test to higher levels of test integration, creating test environments and scenarios representative of both normal and failure operations can be difficult.

The operation of the test equipment itself is often a culprit. As technology continues to push the boundary for greater precision and accuracy, test engineers are challenged to find non-interfering test equipment. When test equipment introduces its own errors, it calls into question the quality of the test results and the end product as well. The question then becomes;

How do we eliminate induced errors to determine if a product is meeting critical performance and accuracy requirements?

Remove friction.

We have a solution for that.

Three Benefits of Air Bearings for the Aerospace Industry

Air bearings remove friction through the use of pressurized air to deliver a stiff gap between hardware. By utilizing the inherent permeability of porous carbon, New Way products supply an even distribution of air through millions of sub-micron holes. This technique overcomes the concerns of the effects of pressure gradients impacting the precision of operations as well as the potential for a damaging bearing crash. New Way’s Porous Media Technology™ provides a robust design allowing a customer to achieve nanometer levels of precision, each and every time.

This technology and approach for removing friction are ideal for use in the aerospace industry for a number of reasons:

This technology and approach for removing friction are ideal for use in the aerospace industry for a number of reasons:

- Improved Product Performance

With friction removed, engineers are able to obtain an accurate, honest assessment of a product’s performance. The use of air bearings allows for quicker identification of root causes and confidence in product design. This approach is useful from the lowest levels of component testing all the way up to the integration of the complete product. Integration of advanced technologies in the aerospace industry can make it difficult to isolate true trouble spots. - No Induced Vibration

With air bearings, there are no operating/moving parts to either contribute errors during a test or to cause damage to sensitive components due to vibration. - Reduced Maintenance Time & Cost

The use of air instead of traditional lubricants removes the need for cumbersome periodic maintenance. With no wear, components last longer, which can be especially ideal for use in products where periodic maintenance is not feasible (e.g. space-based missions).

Let’s look at several applications harnessing these benefits of air bearings in the aerospace industry and beyond.

Four Example Applications of Air Bearings in the Aerospace Industry

- Attitude Control System Simulations

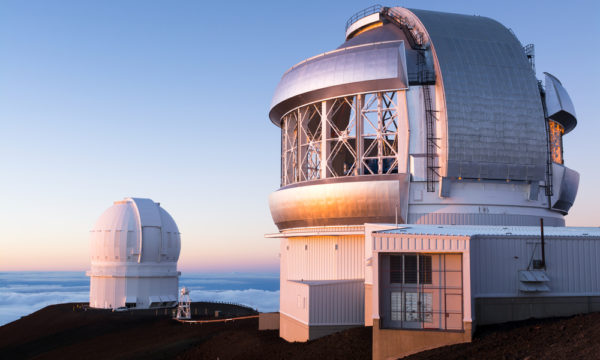

Air bearings have been used for decades to provide a simulation environment for satellites. The satellite is essentially floated on a surface much like an air hockey table to provide a space-like environment for the satellite. This type of environment aids in the precision assessment for critical docking and rendezvous scenarios. The precision required for these scenarios makes the use of traditional bearings inadequate, as they contribute too much friction to enable an accurate assessment. The reliability of the superior precision offered by air bearings is one reason why they have also been used in ground-based astronomy observatories such as The Keck Observatory and the European Southern Observatory’s Very Large Telescope. - Torque Assessment

Air bearings can also be used to test torque and power output. The use of traditional bearing solutions is often not capable of producing the ‘golden reference’ needed during testing given today’s stringent performance requirements. By removing the errors induced by friction, the resultant torque and power can be assessed to determine true engine/product performance. - Product Line Safety

Air bearings can also be used to transport heavy loads within a production facility. With friction removed, the product is able to be lifted and floated in the assembly plant, saving time and also improving safety for employees. This method also minimizes the potential for damage from vibrations to products inherent with sensitive components. - Engine Operation

Increasing engine efficiency and improving ‘green’ operations is a critical focus of many industries, including the turbomachine industry. The industry is making strides at improving engine production and operation by utilizing air to separate the shaft from the bearing, instead of traditional oil lubricant. This non-contact approach improves engine efficiency by removing friction and the inherent energy losses it creates. Removing the need for oil and lubricant from the picture reduces maintenance time and cost, allowing increased operation of aircraft or extending the life of operations for components used in space-based applications.

Let Us Help You!

New Way offers a wide array of standard products as well as custom solutions all designed to remove friction. Whether you are looking to increase the confidence in testing, to transport, or to improve the efficiency of your operations, we are confident we have a solution to meet your needs. Contact us today for a complimentary consultation on using air bearings in your aerospace application!