Don’t miss this ONE key differentiator when considering non-contact air turns!

The roll-to-roll (R2R) processing industry continues to expand, particularly with the growing demand for flexible electronics. Design engineers are exploring options to reduce damage and contamination to improve product quality and quantity. The choice of rollers in the system is vital to meeting these goals. Air turns provide an alternative to conventional contact rollers, offering contactless conveyance, reducing maintenance, and contamination/damage. There are different design approaches for air turns, including New Way® Air Turns which use proven Porous Media Technology™. To understand the differentiating features, let’s look at how non-contact air turns work.

Exploring the History

Air turns are a natural extension of air bearings, which have been providing a contactless solution to the semiconductor industry for precision and manufacturing speed. With the nature of the industry shifting to more flexible substrates, such as photovoltaics (PV) and printed electronics, air turns apply the same technology principles as air bearings.

Basics of Non-Contact Air Turns

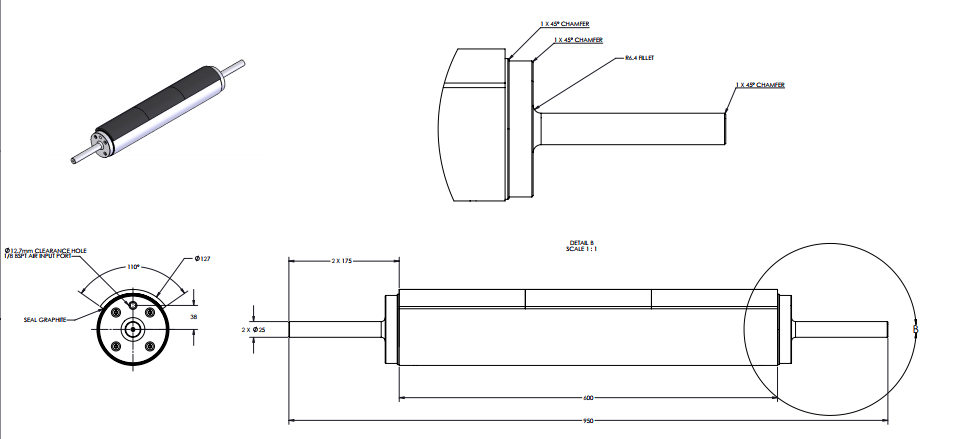

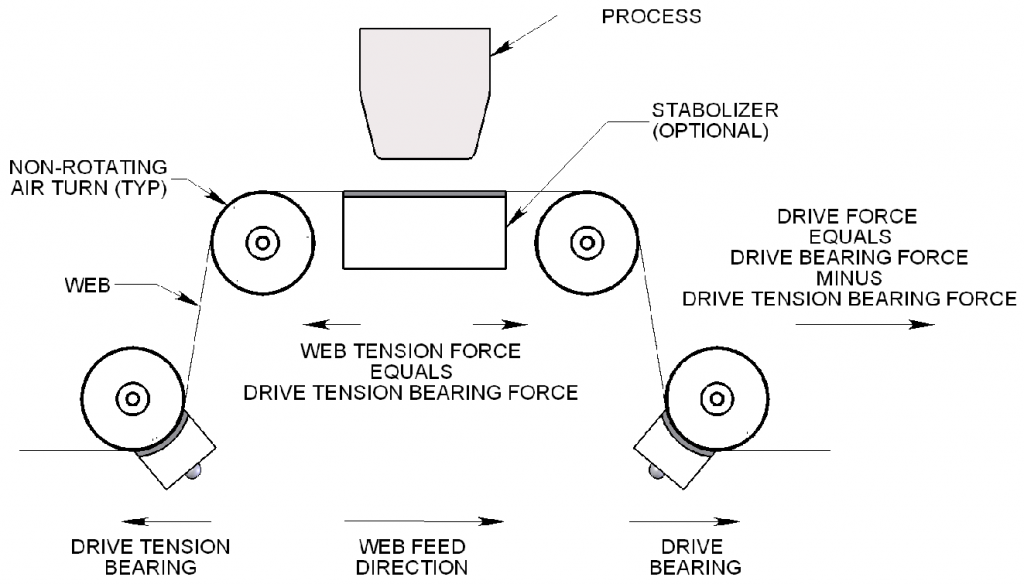

Air turns use a thin and stiff layer of pressurized air to convey a substrate throughout a roll-to-roll process. Similar to an idler roller, the web is wrapped over the air turn as the air is distributed over the entire cylindrical surface. Despite the name the air turn typically does not actually ‘turn’ but uses the pressurized air to ‘float’ the material. The air pressure can be modified to support the material requirements as well as to manage web tension. Since there are no rotating components, maintenance is significantly minimized over traditional contact rollers.

The ONE Question to Ask Before Deciding on an Air Turn

While moving away from contact rollers to air turns is a step in the right direction, there are still options within the air turn design that improve the reduction of contamination and defects. The one question to ask about an air turn under consideration is:

How is the air distributed?

The distribution of air is critical to understanding how non-contact air turns work. There are traditionally two methods for distributing the air throughout an air turn cylinder:

1. Orifice Compensation

Air is provided through one or more hole(s) or grooves to provide lift.

2. Porous Media

Air is delivered through a permeable material formed with millions of holes that allow the distribution of air.

The difference in these two designs directly correlates to the evenness of the air distribution. Orifice technology is known for exhibiting pressure gradients, which can result in contact with the substrate causing damage or contamination. This can become especially problematic with large webs that are becoming more prevalent as products like flexible screens hit mainstream production, or with coating applications. With the use of porous media, the air is evenly distributed, ensuring there is never any contact.

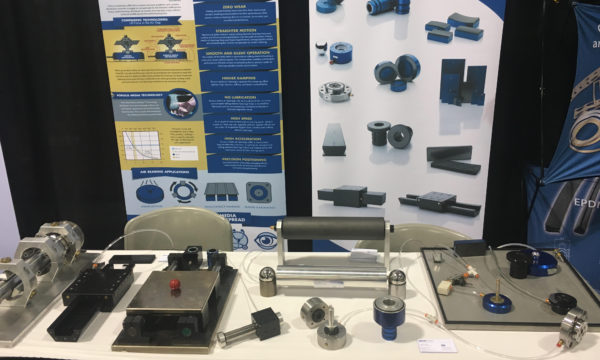

Leading the Way with Porous Media

New Way has a 25-year history using its Porous Media Technology manufacturing air bearings for the machine tool, semiconductor, and medical industries. New Way’s Porous Media Technology distributes air through millions of sub-micron holes removing friction and wear. New Way has revolutionized the Flat-Panel Display (FPD) manufacturing market by using its Porous Media Technology in its development of air bars. New Way Air Turns are a logical step from air bars which apply the same technology in a cylindrical fashion to move a variety of substrates through the roll to roll process.

New Way Air Turns can also be coupled with their sister product, Air Bearings, to manage web tension control. With the web positioned between two air bearing films, high pressures may be exerted on the film in compression. Air shear in these air bearing gaps act directly on the flexible film for controlling film tension between rollers, as well as spreading tension across the web (along the length of a roller.)

3 Direct Benefits of New Way Air Turns for the Converting Industry

One of the most powerful benefits of New Way’s Porous Media Technology in its air turns and air bearings, is its ability to fine-tune areas that pose challenges within the system. Let’s look at three of these challenges in the converting industry.

1. Web Tension

Maintaining appropriate web tension is critical to avoid wrinkles and contamination, particularly when dealing with coating applications. Revenue can be impacted because of damage to the web and the downtime required to mitigate the situation. New Way Air Turns coupled with Air Bearings allow even distribution across the cylinder allowing for improved control of the web between rollers as well as across the entire web (length of the roller.) Not only could wrinkles be removed, but it may also be to stretch and align a pattern on a web without contact with either side of the web. This could obviate the need for spreader and tension bars.

2. Temperature Control

Rollers may need to be heated or cooled during operations to handle materials and/or coatings. Similar to how web tension is controlled, the use of New Way Air Turns and Air Bearings together allows the temperature to be driven from both sides of the web simultaneously. Because of the high relative pressure (1 to 3 atmospheres) and such high velocities of air in the air gap, the boundary layer of air associated with the surface of the film can be scrubbed. This is essentially increasing convective film coefficients (wind chill.) Not only is this more effective in driving the temperature, but the need for mechanisms to heat and cool the rollers is eliminated.

3. Precision Positioning

Today’s products require manufacturing operations with micro- and nano-precision. The surface averaging in its Porous Media Technology make New Way Air Turns ideal for accomplishing precise positioning operations.

While air turns themselves are not new, New Way offers higher pressure/lower flow web handling components that create much higher gas velocities relative to the film surface. The minimal gap size increases damping and the precision with which the web may be handled.

Are You Ready to Join Us in Turning Over the Converting Industry?

With the boom in the converting industry, particularly with flexible electronics, air turns are a clear choice to enhance production to meet customer demand. Understanding how non-contact air turns work as well as how the air is distributed is critical to identifying the right air turn product for your problem.

New Way’s Porous Media Technology offers a superior advantage when it comes to contamination concerns, web tension control, and temperature control. Contact us today for a complimentary consultation for using New Way Air Turns to improve your web handling production. Or, if you’re ready to join the movement now, contact us with the desired diameter, length, and interface design for your air turns. We’re ready to turn your production up!