Explore proven Gas Bearing Technology at 2017 TPS by New Way

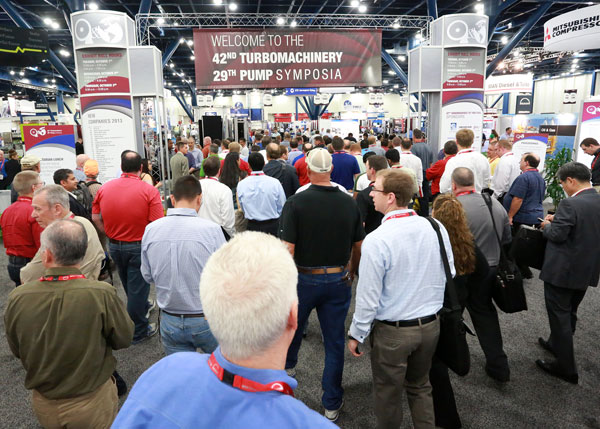

The 46th Turbomachinery and 33rd Pump Symposia (2017 Turbo Symposium), is the industry’s leading gathering of rotating equipment and pump engineers and technicians worldwide, spanning the oil and gas, petrochemical, power, aerospace, chemical and water industries. The 2017 Turbo Symposium (2017 TPS) is organized by the Turbomachinery Laboratory, as part of the Texas A&M Engineering Experiment Station (TEES) and The Texas A&M University System. The 2017 TPS is scheduled for December 11-14 in Houston, TX at the George R. Brown Convention Center.

The 2017 TPS, offers a wide array of technical programs, though the centerpiece of the Turbo Symposium, are the exhibitions of products and services of the world’s leaders in turbomachinery and pumps. As an exhibitor at the 2017 Turbo Symposium, New Way (Booth 2611) is showcasing three products designed and proven to meet the robust challenges of this industry.

3 Transformational Products for the Turbo Industry by New Way

Bently BearingsTM

In 2016, New Way acquired Bently Pressurized Bearing Company, a manufacturer of precision radial bearings for the Turbomachine Industry. Bently Pressurized Bearings utilize Externally Pressurized Gas Bearings to modify the input pressure, which increases the stiffness of the bearing, allowing for increased stability. Combining Bently’s original design with New Way’s proprietary Porous MediaTM Technology results in Externally Pressurized Porous (EPP) Technology. Bently BearingsTM by New Way offer both radial bearings and axial/thrust bearings which prove to be superior to foil bearings offering:

- No wear (Frictionless motion)

- No dry running at start-up/stop

- Higher loads

- Increased stiffness

The removal of friction in Bently BearingsTM eliminates wear issues, which drive maintenance requirements, bringing operations to a halt. The increased load capacity and stiffness offered by Bently BearingsTM meets the demand for oil-less solutions, allowing for broader use in turbomachine applications, as opposed to the small subset able to be served by foil bearings.

Bently BearingsTM can be retrofitted to replace foil or rolling element bearings. Using the EPP Technology, the bearings are able to operate using process gases and up to 400° C with oxygen and higher without oxidation issues.

A specialized subset of Bently BearingsTM by New Way are the balance bearings. Hard or soft mount compatible, the Bently balance bearings balance shafts without contacting hard rollers. New Way’s design improves rotor-balancing through proven EPP Technology. Balance bearings provide a more precise axis of rotation with a cleaner signal for higher resolution in balancing.

New-SealTM

With the foundation of EPP Technology, New Way Air Bearings launched New-SealTM to provide a non-contact shaft sealing solution that functions as both a bearing and a dry gas seal simultaneously. New Way’s Porous MediaTM produces a contiguous face on the bearing so it looks like a dry gas seal. Couple this with the fact that the pressure is highest in the bearing gap, it acts as a dry gas seal securing liquids, gases, fine powders, and slurries. New-SealTM manufacturers face (thrust) seals and circumferential (radial) seals offering:

- Potential to operate on process gases

- Oil-less solution resulting in low-maintenance

- High speeds without heat

The New-SealTM ability to operate using source gases allows operational synergies, particularly for turbomachine applications in the Oil & Gas industry. Operating at high speeds without heat translates to less wear of components. Coupling that with the oil-less solution offered by New-SealTM, maintenance downtime affecting production is significantly decreased.

New-ValveTM

New-ValveTM utilizes the proven EPP Gas Bearing Technology to mitigate emissions while providing Frictionless Motion®️. Additionally, the EPP Technology results in ease of operating the valve, including:

- Minimizing breakaway torque issues

- Removing need for special tools to open/close valves

- Eliminating physical strain from manual actuation of valves

Through EPP Technology, New-ValveTM has greater controllability of the input pressure, which impacts breakaway torque. This allows for better understanding and compensation for breakaway torque in operations. Eliminating special/custom tools and manual labor to work on the valves saves everyone time, money, and unnecessary wear on the body!

New-ValveTM can be used in place of traditional valves or retrofitted to replace traditional valves.

Drop by our Booth!

Come visit us at Booth 2710 at the 2017 TPS to see demonstrations of New Way’s proven Externally Pressurized Porous Gas Bearing Technology in Bently BearingsTM, New-SealTM and New-ValveTM. Whether you are starting a new system or looking to retrofit, New Way’s team of engineers is prepared to answer questions on how New Way’s products can provide a frictionless solution to your bearing, seal or valve challenges. Or if are you ready to take the next step now, contact us today for your complimentary consultation!