Flexible Web Handling has emerged as a rapidly growing space in recent years, and New® Way has been at the forefront of developing technology to support these products. Following the success of our Air Bars for the production of Flat Panel Displays (FPDs), we wrapped our proprietary Porous Media™ substrate around the exterior diameter of a shaft to create our Air Turns™. This product allows for non-contact handling of flexible material and substrates, from plastics and films to metals and cutting edge technologies like flexible displays.

Here, we’ll cover the state of the industry, from legacy applications to the current landscape. We’ll also discuss what the future holds for flexible web handling both in terms of manufacturing technologies and the end use components themselves.

State of the Industry

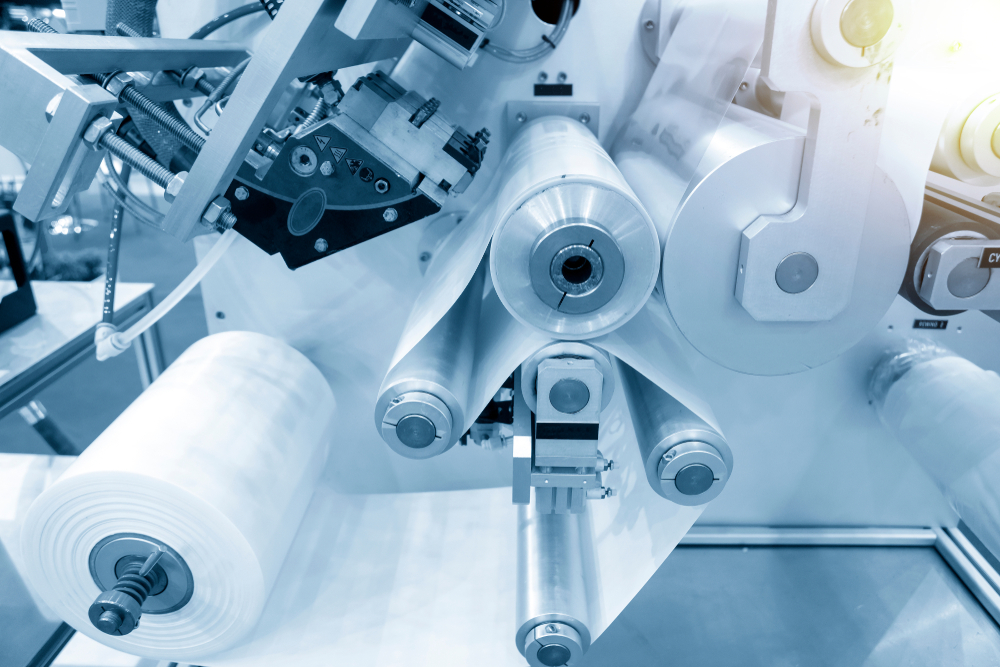

Roll-to-roll processes and flexible web handling come into play during the production of a vast range of products. Sheet metal, consumer textiles, plastics, and aerospace grade composite plies all require tensioned rollers during their production and packaging process. As a result, each manufacturing line required dozens if not hundreds of contact rollers.

Roll-to-roll processes and flexible web handling come into play during the production of a vast range of products. Sheet metal, consumer textiles, plastics, and aerospace grade composite plies all require tensioned rollers during their production and packaging process. As a result, each manufacturing line required dozens if not hundreds of contact rollers.

The sheet metal market alone is valued at 262.2 billion dollars in 2022. You can imagine the roll-to-roll market which must exist to support this production infrastructure. Until recently, flexible substrate handling was accomplished exclusively through the use of contact rollers, pulling the material across its surface to introduce tension. While this is simple and effective, this method also introduces many errors. From contact induced material defects to a lack of in-situ product control, New Way saw many places Porous Media could improve on the old-fashioned method.

The Development of Air Turns

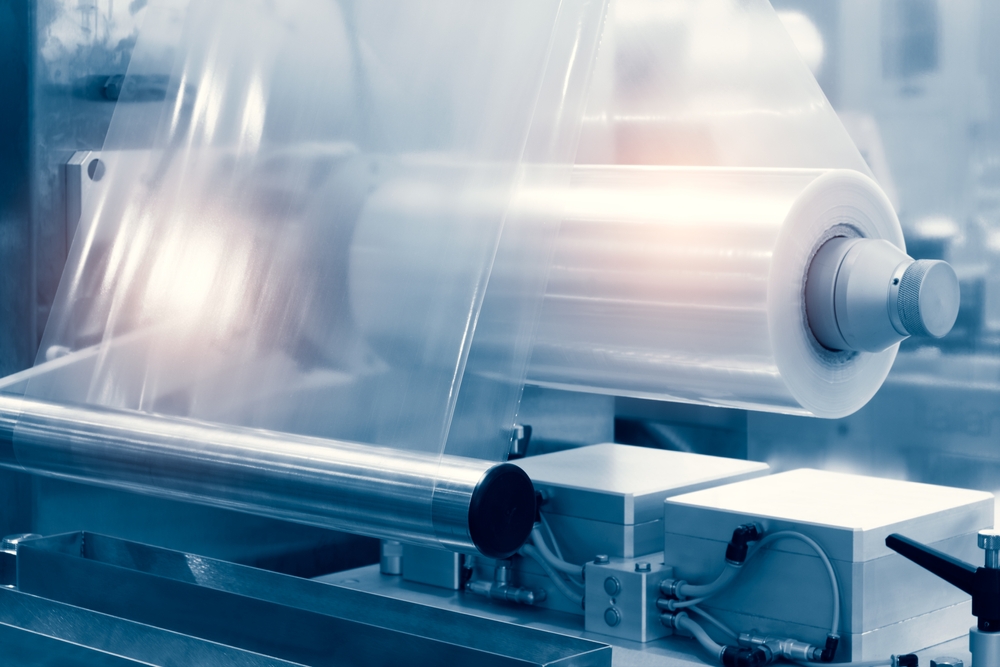

New Way evaluated the history of roll-to-roll processes to inform the development of our Air Turns™. Simply put, the Air Turns use our foundational Porous Media Technology to suspend your material above the surface of the Air Turn, allowing for the substrate to glide over the rollers while retaining tension between two individual air turns. This system immediately removes surface induced defects from the contact between your substrate and the roller, but we find even more benefits as well.

Because Air Turns feature an adjustable inflow pressure, tension between two individual Air Turns can be adjusted on the flow to properly tension your material. Additionally, the viscous shear layer of the air film itself acts as a microscopic scrubber, removing small particles from the material surface and wicking away excess moisture which may have remained from a prior production step.

Flexible Web Handling Through Air Turns

Air Turns have already made an impact on the flexible web handling market. MultiPlastics, Inc provides almost 60% of the world’s polystyrene window film. They wanted a new system to reduce maintenance on their 24/7 production lines. The Air Turn removed contact based defects, and provided cooling as the films leave a 500 degree Fahrenheit production step. New Way also worked to develop High Temperature Air Turns, which are now available for wider purchase.

For research applications, New Way partnered with IBS Precision Engineering to perform metrology studies on the use of our Air Turns for roll-to-roll printing. This white paper by Dr. Theresa Spaan-Burke of IBS lays out how Air Turns provide unique capabilities to flexible web handling, reducing web height variations from a maximum of more than 250m to below 5m.

Furthermore, because there exists an air gap on both sides of the material being transported, in-situ interferometry can be used to measure the fly height. This allows for production engineers to adjust tension as required. Other benefits also arise from contactless motion, including lateral web steering and a lack of an accumulated static charge on the transported film.

Looking to the Future

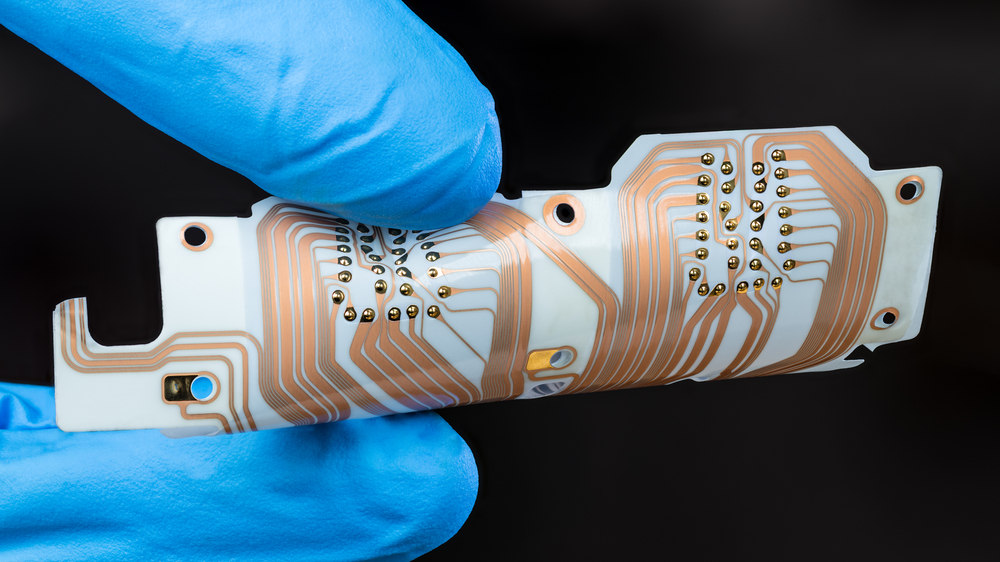

Flexible displays have rapidly moved from prototypes to a matured technology. The flexible display market is currently valued at 6.98 billion dollars, and is expected to maintain a staggering compound annual growth rate of 28.1%. The industry clearly intends for this technology to revolutionize many legacy applications and devices.In fact, Samsung’s Galaxy Z Fold smartphone is already on its fourth iteration, and the industry isn’t slowing down anytime soon. LG has also already proven flexible and stretchable display technologies.

This technology still requires many of the same production processes as more traditional textiles and films. However, it also now carries the added complication of FPD cleanroom standards. These new demands will transform the Air Turn from a luxury to a necessity. The Air Turn’s cleanroom compliant nature and non-contact operation will make it a staple technology for any flexible web OEM ready to take the leap, future proofing their roll-to-roll processes for decades to come.

Contact Us

If you want to learn more about how New Way brings frictionless motion to the flexible web industry, download our Air Turns 101 brochure and reach out to us!