Air bushings are one of the many configurations of air bearings available from New Way®.

When assembled onto G6 tolerance standard steel shafts, they reduce rolling friction between the shaft and anything attached to the air bushings. Easily swapped with rolling element bushings, air bushings provide the advantages of frictionless linear motion, precision positioning and heavy load capacity. By operating on a thin film of air, these air bearings avoid surface contact and the need for lubricants while maintaining superior performance characteristics.

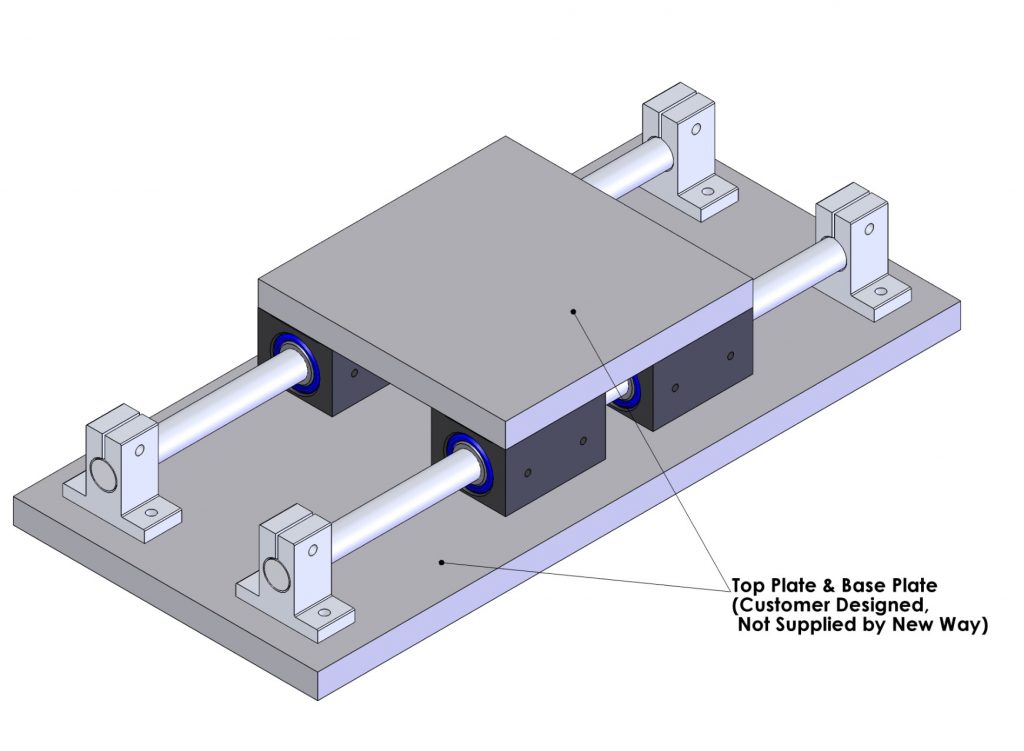

New Way offers standard mounting components to ease the integration of air bushings and ensure their proper alignment. For example, black anodized aluminum mounting blocks enable the easy assembly of custom slides using New Way Air Bushings. Compatible with both metric and U.S. air bushing versions, New Way mounting blocks, also known as pillow blocks, are available in seven sizes ranging from:

New Way offers standard mounting components to ease the integration of air bushings and ensure their proper alignment. For example, black anodized aluminum mounting blocks enable the easy assembly of custom slides using New Way Air Bushings. Compatible with both metric and U.S. air bushing versions, New Way mounting blocks, also known as pillow blocks, are available in seven sizes ranging from:

- 75 mm or 3.0” ID

- 50 mm or 2.0” ID

- 40 mm or 1.5” ID

- 25 mm or 1.0” ID

- 20 mm or 0.75” ID

- 13 mm or 0.50” ID

- 0.25” ID (US version only)

New Way air bushings are designed with O-rings located on the outside diameter of the air bushing housing to assist with alignment and positioning. Two common methods for mounting air bushings in a standard New Way mounting block or bore in a custom housing are:

O-Ring press fit (flexible mount).

Standard New Way air bushings are supplied with 4 o-rings, two inner and 2 outer rings. The two inner o-rings form a seal to allow the pressurized air to supply the air bearing. An air supply hole can be located anywhere on the mounting block between the two inner o-rings. This mounting method allows the air bushing to “float” somewhat in the housing to allow the air bushing to align axially with the shaft and accommodate misalignments of air bushings and shafting of up to .002” (.050 mm). Install the two outer o-rings for a flexible mount with additional stiffness. Use Isopropyl Alcohol as a lubricant when pressing the bushings into a mounting block or housing.

Bonded in place (hard mount).

This method requires the use of 4 o-rings. The inner two o-rings form the seal for the air supply. The outer two o-rings form two annular cavities with the inner two o-rings. These cavities are filled with an epoxy that will fix the air bushings in precise alignment with the shaft. In this method, the air bushings are positioned in the housing with the 4 o-rings. Again, use Isopropyl Alcohol as a lubricant before pressing the bushings into a mounting block or housing. Align the shafts and supply compressed air to the air bushing via the supply hole located between the inner o-rings. The epoxy is then injected through holes in the housing so that the cavities between the outer and inner o-rings are filled. The air supply to the air bushing must remain on while the epoxy cures. If custom housings are used, be sure to supply an additional hole in the cavities so that the air can escape when the epoxy is injected.

In addition to a standard line of air bushings and mounting blocks, New Way manufactures custom bushings as well as custom housings in heavy duty materials, larger sizes, and other special configurations. Find out more about New Way air bushings and mounting blocks by visiting the website.

Check out the video that demonstrates how to insert an air bushing into a mounting block at https://www.newwayairbearings.com/news/blog/2117/drew-devitt-introduces-new-ways-standard-air-bushing-product-line/.

Contact us today for a complimentary consultation