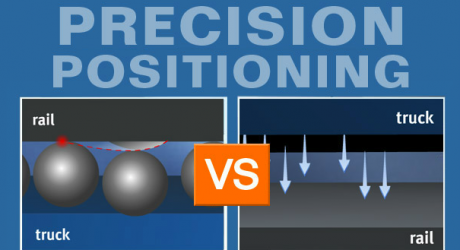

When your application requires precision positioning, it is important to understand that rails and guideways often exhibit flatness deviations. Some of these are inherent…others may develop over time. Either way, the momentum of the balls in a rolling element bearing actually amplify the unwanted motion of the bearing. In fact, rail-ball contact further damages both…

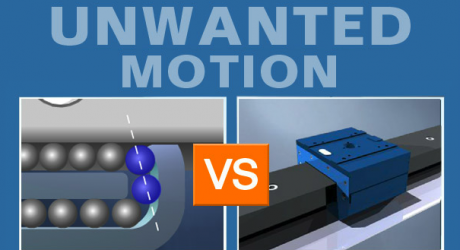

Unwanted Motion

A direct comparison of porous media air bearings and conventional rolling element bearings shows that, when using the latter, there is a significant amount of unwanted motion in all directions. This is because there are minute differences in the size of the balls themselves and the balls are also slightly larger then the clearance in…

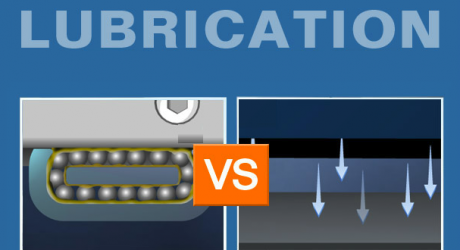

No Lubrication

Mechanical contact requires lubrication. Because conventional rolling element bearings rely on the movement of balls against a guide surface, lubrication is a standard part of ongoing equipment maintenance. But lubricant migrates to the guide surface, and also causes out-gassing, often effecting the process at hand or the environment. Maintenance is not only necessary, it can…

Acceleration

Conventional rolling element bearings are limited in their acceleration capabilities because of the rotating inertia of the balls in their guideways. These balls start and stop at inconsistent points. They slide, skip and skid. This causes precision problems, especially for applications with light loads over short distances. In a direct comparison, porous media air bearings…

Speed

There is an order of magnitude difference which separates the speed capabilities of conventional rolling element bearings from their porous media air bearing counterparts. Contact with the rail or guideway, and multiple different ball velocities, limit the speed capabilities of conventional rolling element bearings to 3-5 m/s. Porous media air bearings are a completely non-contact…

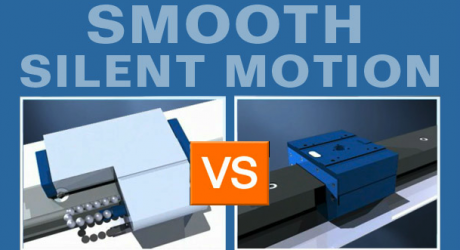

Smooth and Silent Motion

Any comparison with porous media air bearings must include a recognition of the constantly changing, multiple forces which act on the raceway integral to the function of the competitive rolling element bearing. The changing directions of the balls within this raceway result in velocity ripples which, in turn, compromise stability and impact performance. These velocity…

Zero Wear

When it comes to wear, contact is, again, the differentiating factor between rolling element bearings and porous media air bearings. Quite simply, balls show wear from mechanical contact. Over their lifetime, this causes friction changes, resulting in inconsistent machine characteristics. In fact, in mechanical contact systems, wear is a function of load, acceleration, velocity, distance,…

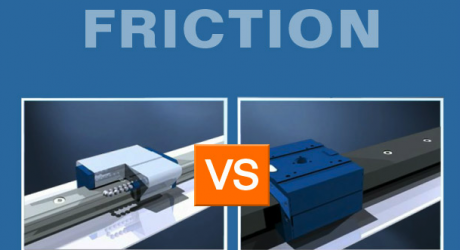

Zero Friction

The comparison between conventional rolling element bearings and porous media air bearings begins and ends with contact. Contact, and the resulting high stiction, often causes the rolling element bearing to overshoot its mark. This causes resolution problems, especially with light loads over short distances. New Way Porous Media™ air bearings are entirely non-contact, so there…

Air Bearing Basics

These short videos provide an overview of New Way Porous Media Technology™, as well as video highlights of specific products.

What Is a Conveyor Air Bearing?

Now called New Way® Air Bars, this animation example shows how the combination of air and vacuum enables both the noncontact conveyance and sub-micron level control of substrates during a Flat Panel Display (FPD) manufacturing process. 0:49 (No Audio).

What Is a Radial Bearing?

In this animated example of a Computed Tomography (CT) Scanner, New Way’s Radial Bearings provide noncontact, high-speed rotary motion through a 5-micron air film, without noise and wear, improving operations. 1:09 (No Audio).

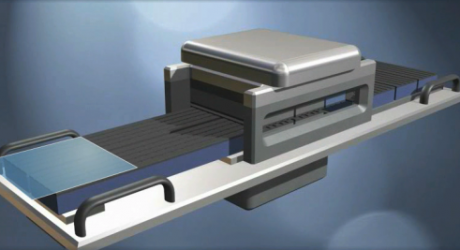

Air Bearing System Technology

This animated example shows how Porous Media™ air bearings create a stiff film of air by forcing air through millions of sub-micron sized holes, creating noncontact linear motion for a Coordinate Measuring Machine (CMM). 0:37 (No Audio).

New Way Products

Here you’ll find a number of longer-format videos designed to introduce you to New Way Air Bearings products, their functions, and the benefits that they can provide for engineers in various industries or markets.

C-Series Conveyor Air Bearings (Now ‘Air Bars’)

Now called New Way ‘Air Bars,’ this more-detailed animation shows how the combination of air and vacuum enable both the non-contact conveyance and sub-micron level control of substrates during a manufacturing process. The animated example is a Flat Panel Display (FPD) manufacturing process.

Clean-Dry-Coat Technology Concept

This brief animation shows how New Way Conveyor Air Bearings (‘Transition Zone Air Bars’) and Precision Chucks (‘Precision Zone Air Bars’) can be used to create a simplified, in-line system for cleaning, drying and coating substrates during the FPD or PV manufacturing process.

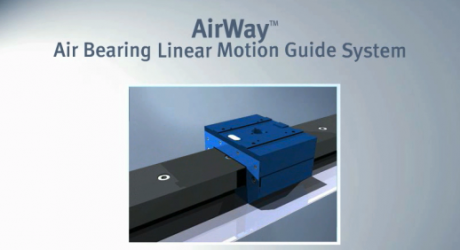

AirWay Linear Motion Guide (LMG) System

This more-detailed animation examines the structure, installation and benefits of the New Way AirWay Linear Motion Guide System. In fact, it is the compilation of many of the shorter animations in the Technology Comparison section below, plus a useful Reference section.

Contact us today for a complimentary consultation